INTERNATIONAL

Dibella, as the textile care industry becomes ever more concerned about textile longevity and sustainable best practice, has come up with some novel solutions for ensuring a world of circularity, including its Circular Textiles range. Its investment in the field of textile recycling and the circularity of its products, includes, for example, participation in external research projects as well as in Dibella’s own circularity projects.

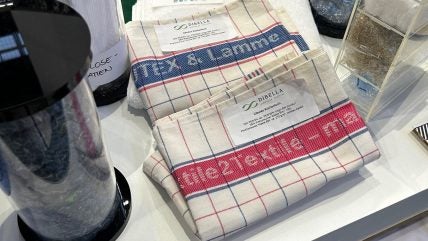

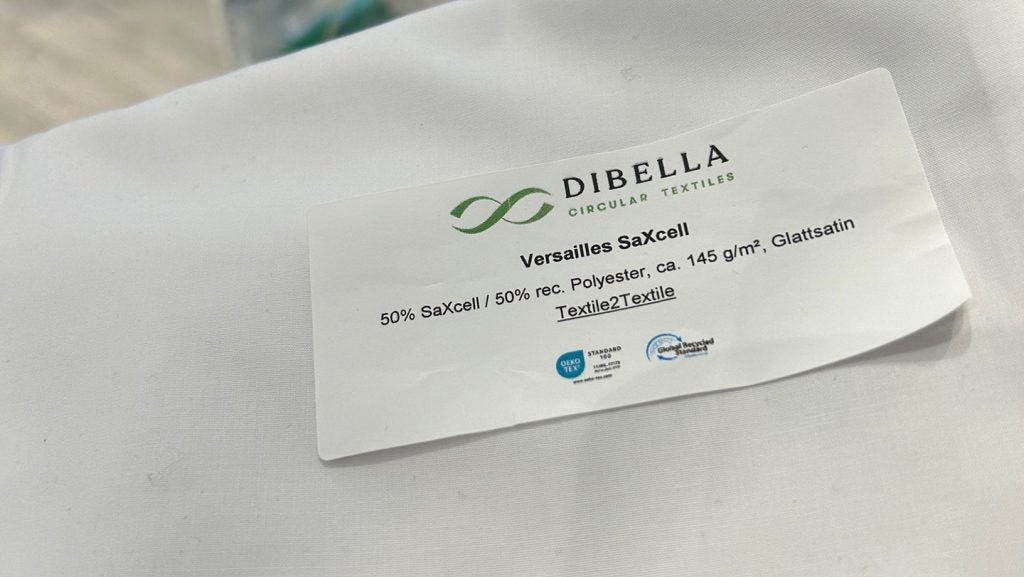

Dibella showcased its innovative textile solutions at Texcare International 2024 in Frankfurt, Germany last November including numerous examples of its linens manufactured with substantial recycled content. To achieves these advances, the company has partnered with Cibutex, a cooperative based in the Netherlands that collects and recycles defined waste textiles and then sends them for industrial fibre-to-fibre recycling.

Large-scale recovery is possible because large batches of similar textiles accumulate in the textile rental service at the end of the use phase. These can be economically processed by specialised recycling companies, the bound raw materials recovered and then returned to the textile cycle.

So far, explained Dibella, the circular project is still limited to contract textiles made of pure cotton and cotton-polyester blends with a maximum share of 50% synthetic fibre. To ensure trouble-free recycling, these textiles must be sorted by composition and be white. For terry towelling, a colour content of no more than 5% is permitted. It is also possible to hand in jersey fitted sheets so long as they are free of elastic bands or other elastic components.

At the same time Dibella showcased its Longlife Textiles range which includes Dibella’s entire core range which is labelled with OEKO-TEX® MADE IN GREEN with the Green Button. This offers a high level of assurance of compliance with the German Supply Chain Act and the related EU regulations. On request, Dibella can also equip the textiles ex works with Datamars transponders and offer textile solutions to save process costs.

Meanwhile, said Dibella: “Good Textiles, our premium range, stands for sustainability and transparency from the cotton field to the finished textile. All products are Fairtrade and GOTS certified and meet the highest human rights, social and environmental standards, some of which go beyond legal requirements. Our Good Textiles also produce 46% fewer greenhouse gases, use 62% less energy consumption, 91% less water consumption and are 100% free of any harmful substances compared to conventional cotton.”

The Green Workwear Dibella brand stands for fair and sustainably produced workwear with a focus on the healthcare sector.

Dibella can and does provide comprehensive information on its services, which offers customers a wide range of simplifications in textile sourcing, storage an labelling as well as process-related challenges and support with marketing and CSR issues.