With Texcare 2024 taking place in November, it is understandable that manufacturers are keeping their cards close to their chests when it comes to new features and models but there is plenty out there to impress even before the big reveal later this year.

According to Nicolas Gostony of Jensen-Group there are tasks a washer -extractor is more suitable for than even the most versatile tunnel washer. “Our largest tunnel washer can handle up to 120 kg in one compartment, processing up to 5 tons of laundry per hour in a highly automated process. However, the laundry’s customers may have linen that for various reasons can neither be washed nor dried in the automated washroom section. Delicate linen as well as contaminated pieces that can be infectious need to be processed separately. For handling reasons, nursing homes may want to process their guests’ personal garments in a process that is separate from the rental linen. That’s why Jensen also offers stand-alone washerextractors and dryers for medium to large wash loads that are a perfect complement tunnel washers and help to increase the flexibility of the laundry offering to meet the end customer’s needs.

The JWE Jensen washer extractor for small to medium volumes is available in loads ranging from 24 to 110 kg. Based on a very simple construction, these free-standing, high-spin machines (up to 360G) are high-performers. The minimum drum spacing allows a fast heating and reduces the water consumption down to below 10l/kg on an average wash cycle. High-capacity inlets speed up the water ingress and heating.

The new JWE 270/600 washer wxtractor is great news for laundries with big volumes, processing 270 kg at one go. Thanks to its 12° two-way tilt and loading hopper, it can support both fully automatic loading and unloading. Delicate or heavily soiled linen can receive excellent washing results thanks to specialized washing programs with customized cycle times, water levels, temperatures, and spin speeds. Also, detergent is dispensed by actual linen weight for maximum wash control.

Meanwhile, JBW Jensen barrier washer extractors ensure the most reliable protection against the spread of germs and bacteria, as they prevent contamination of linen thanks to maximum disinfection. The washer extractor is designed to be installed into the wall, allowing for the loading of linen on the soil side and unloading on the clean side. Volumes can be easily adapted when the business grows, as the JBW is available in a range from 16 to 230 kg.

All machines are designed to offer the highest quality of washing with minimum water, energy and chemical consumption. The design and the use of advanced materials ensure longevity, safety, userfriendliness, and a very cost-efficient operation.

Meanwhile, Lavatec’s LX300 washer extractor series provides the ultimate in productivity and reliability. These high performance machines are designed to run for many years with simple, regular maintenance. Featuring six stainless steel machines, this cost efficient series ranges in capacity from 80 to 530 pounds and includes the 250-pound LX325. With a single inverter drive motor that applies power for the lowest energy consumption at any speed, it translates to high extraction rates and reduced drying times to improve your bottom line.

Kannegiesser’s Favorit Vario stands for washing quality, process optimisation, resource saving and process documentation – for the entire range of articles that can be found in laundries, says the company, demonstrably proud of its achievement. .

Each batch of laundry is washed with exactly the amount of water and chemicals required for the actual batch weight. This ensures high washing quality and the lowest consumption, even when particularly small batches are processed. Favorit Vario even considers the amount of water that is absorbed by the textile or that is added via the dosing of chemicals and steam. it couldn’t be more precise, says Kannegiesser.

At the same time, JET rinsing ensures low fresh water consumption and fast process times, and thanks to the CareWash perforations, even sensitive textiles are processed extraordinarily gently. ‘The high imbalance tolerance of our washer-extractor technology is particularly important for smaller businesses – after all, the processing of minor batches always leads to very different loading quantities in practice.

“With the Favorit Vario, even particularly sensitive textiles (angora wool, poplin or silk, for example) can be processed in an environmentally friendly wetcleaning process instead of drycleaning in solvents. Such processes are characterised by extremely reduced washing mechanics, very long dwell times in the idle drum, strong underloading and the extremely precise maintenance of temperatures and detergent concentrations.

“All this is no problem for the Favorit Vario, even in the basic version! In addition, for such applications, the Favorit Vario is often configured with indirect steam heating for gentle heating and with undivided inner drums for full freedom of movement for the laundry,”comments Kannegiesser.

Lapauw’s 3-pocket machines, thanks to the separate compartments, mean large sheets and duvet covers can be processed in quantity with no bunching and entangling. This substantially increases productivity thus, overall cost, when unloading the washers and when feeding the ironers.

The 3-pocket washer also increases productivity on another level, especially for OPL in larger resorts. Offering the flexibility to wash different types of linen simultaneously in one machine. As long they have the same soil level and material (for example bath towels, face and hand towels and bath mats). With this procedure, the linen comes out of the washers pre-sorted which increases productivity in the finishing aisle.

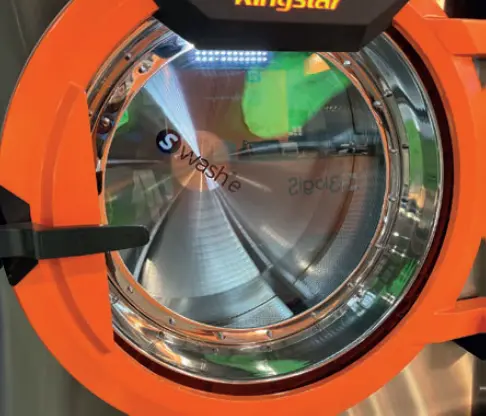

CLM Texfinity’s S.wash e 100/120kg claims an exceptional build quality, according to the company, with SUS304 stainless steel used for both inner and outer drums. This material choice ensures long-lasting durability and prevents rusting, thereby eliminating any potential washing quality accidents due to corrosion.

The series features a a linen feeding port where the junction between the inner and outer drums is designed with a 270° crimping mouth. This design not only enhances the smoothness and strength of the machine but also minimizes the gap, effectively reducing linen damage, Says CLM Texfinity.

The S.wash e incorporates a downsuspended shock absorption design. This includes inner and outer double-layer seat springs, rubber shock absorption springs, and four damping shock absorbers. This achieves an ultra-low vibration level with a shock absorption rate of up to 98%, making it suitable for use on any floor without a ground base.

The intelligent control system integrated into the S.wash e delivers an array of automatic functions including water addition, pre-wash, main wash, rinsing, and neutralisation. With 30 washing programs and five common automatic options, the system offers versatility and ease of use.

To ensure operator safety, the large stainless steel loading door, coupled with electronic door locks controlled by a computer program, ensures the door only opens post high-speed extraction, significantly reducing the risk of accidents.

The intelligent weighing system gets gto work, automatically adjusting water and detergent intake based on linen weight, which results in significant savings in water, electricity, steam, and detergent costs, while maintaining consistent washing quality.

The tilting unloading design, with a forward tilt of 15 degrees, aids easier and smoother unloading. A 400G extraction capacity leads to reduced drying times and increased daily output. The large diameter water inlet and optional double drainage system further shorten washing times, enhancing overall efficiency.

The S .wash e is also available in versatile 18/25kg and 40/60kg versions.

Girbau beleives washer extractors are the forgotten heroes, tirelessly tackling mountains of linens, garments, and textiles with precision and efficiency. Girbau’s says its Genius series of washers emerges as a reference of innovation and efficiency. “Addressing the industry’s critical pain points and challenges, such as high investment, fragility of equipment, usability from operators, or lack of control from the full laundry, Genius sets a new standard for excellence,” sauys the company

Built for durability and robustness and engineefred to withstand the demands of commercial use, the Genius series has reinforced structural bolting, advanced accelerometer technology, and a proven ultra-resistant touchscreen, Genius “sets a new standard for reliability’.

Genius is also a champion of efficiency, says Girbau. “Its formidable spin force reduces washing times by 10%, reducing electricity and water consumption while maintaining high cleaning standards. Its optimised weighing system ensures precise chemical dosing tailored to the real weight of the linen, leading to significant savings in resources and minimizing environmental impact.

With its with an intuitive touchscreen and a 360-degree visor light, these machines offer enhanced visibility of machine status, empowering operators to make informed decisions in real time.

Integrated with Girbau’s IoT platform Sapphire, these machines offer remote access to manuals, real-time alerts, and complete program editing, putting control at your fingertips and revolutionizing laundry operations.

Domus has developed a new state-ofthe art product range with promised low consumption and high energy savings for their entire life span. Gemma Colomer says that when it comes to investing in new laundry solutions, the machines are the visible part of an iceberg but there is an awful lot more going on under the waterline. She says that Domus pays attention to the part of that unseen part of the iceberg to optimise expenses, arguing that what matters is not the purchase price of a machine but the total cost of ownership during its life cycle.

Domus washer-extractors offer a high G factor for more efficient spinning. It claims its DHS washer-extractor with its 500 G spin can reduce topical drying times from 45 minutes to just 25 minutes and offer a 50% energy cost reduction, low water consumption via Domus touch II technology. On a 100% cotton towelling full load in a 28 kg washer its figures show consumption of just 6.6L/kg including pre wash, wash and three rinses.

Water savings are achieved by using the inbuilt weighing system which can make significant savings on part loads. Chemicals savings, meanwhile, are achieved via the Touch II microprocessor which allows configuration of the machine to levels to achieve chemicals savings as well as water and energy savings, no matter the load level. The lesser the load, the more the savings.

Water recovery is via Domus’ ECOTANK and ECOTANK XL. Ecotank XL is a new centralised tank that can be connected to one or more machines. Each tank is 1.000 litres, with 1 to 3 tanks available.

“In a DHS-80C Touch II washer we can achieve up to 56% water savings thanks to Ecotank XL if we load 60% of the capacity with towels, in the washing machine alone it will use 656 litres but in a washing machine with Ecotank XL it is just 288 litres,” says Colomer.

As for energy, Domus claims it can achieve 12% electricity savings with the same load and Ecotank XL. Washing machine on its own will use 21.37 kW/h and with the washing machine hooked up to an Ecotank XL you get 18.80kW/h, says Colomer who adds that the data is based on tests with an 80kg washer with a 60% load with towels.

Barrier washers

Krebe Tippo last year changed its standard barrier washers from a mechanical and also electrical/ software point of view and created a completely different product. Products were custom made specifically to the needs of customer. In 2024 the company will market its 516 Smart Drum concept where machines will be equipped with RFID readers and a data base to eliminate the risk of linen being lost or mixed.

With its Mediwave range, Lapauw also offers barrier washers which fit into the increasing demand for hygiene since Covid, and meet targets on safeguarding end users are demanding.

Domus barrier washers range from 27 to 70 kilos to meet different needs. In addition, they are equipped with the ET2 microprocessor, with a 7″ scree n that allows efficient control of each wash and can be configured in 37 languages.

Danube has barrier washer with different load capacities ranging from 27 to 70 kilos to meet different. In addition, they are equipped with the ET2 microprocessor, with a 7″ scree n that allows efficient control of each wash and can be configured in 37 languages. Danube’s sanitary barrier washers have been designed within strict hygiene and safety parameters, as hygiene must be ensured. To avoid contagion, the machines used for washing must comply with RABC standards to ensure the highest level of hygiene.