The face and voice of the environmental campaigner David Attenborough have spurred awareness of the ‘plastic soup’ being created worldwide by the breakdown of plastic over the land surface and in every part of the Earth’s oceans. Despite the potential dangers of this being flagged up many years ago, national legislations on every continent have been culpably slow in prioritising technical R&D to identify a solution. The result is steadily increasing plastic microparticle pollution in what was once a clean international resource – the seas of the world.

The substantial research contribution, to the essential knowledge needed, now being made by leading universities and commercial companies worldwide, will have implications for every user of textiles in every country, from textile rental and national healthcare right down to individual households using domestic washing machines.

Occurrence of microplastics

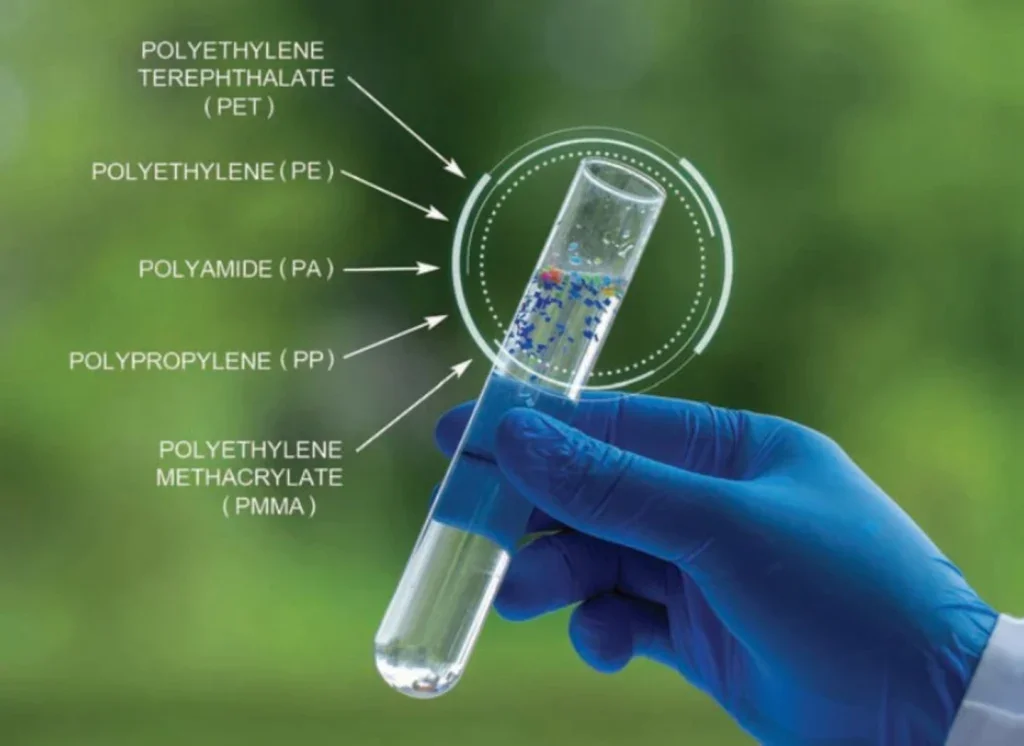

Micro-plastic particles have now been found in ever increasing numbers over every land mass (including the summit of Everest) and down to the deepest ocean troughs. A recent survey of bottled drinking water (reference 1), using the latest automatic counting techniques, found 260,000 nano-sized plastic particles per litre! A micrometre is one millionth of a metre; a nano-metre is 1000th of a micrometre, so it is not surprising that these particles are not removed by most commercial filters. The problem with crafting effective legislation for the purity of our drinking water and food with respect to microplastic contamination is that we do not yet know the safe range of size or number, or even which plastics might represent the worst hazard.

One disturbing finding has been the incidence of chemicals known to be harmful, in recycled plastic items (reference 2). Presumably some or all of these have been created during the recycling process, which opens a new raft of problems and research needs. This could mean that encouraging a greater uptake of recycling habits is not yet the benign solution it appears to be.

Another disturbing incidence of microparticle contamination has been found on food in plastic wrapping. The research was carried out on food in virgin wrapping, so the contamination found is unlikely to be from any recycling process.

Effect of microplastic particles on humans

Recent assessments of microplastic particles in human tissue have found them in human lungs (reference 3) and in human brain tissue (reference 4). Work to determine what effect, if any, this has on the function of these organs appears so far to have been confined to experiments with rats.

It would be both naïve and irresponsible to assume that the now widespread appearance of particles throughout the human body is non-malign, but LCN has not yet found any research being carried out that might indicate how severe any effects might be and what is the range of size, concentration and type of plastic particle that might be tolerated without harmful effect.

Removal of microplastic particles from the environment

Before any remediation of the problem can be implemented, it is essential that contamination of the environment with micro-plastic particles be halted. The worldwide problem is massive, but the first step must surely be to halt the discharges that are making it worse by the day. Fortunately, some brave and far-sighted politicians have taken initial action. California has now legislated for all textiles containing polyester fibre to be clearly labelled with the percentage. This presumably reflects the finding, previously reported in LCN, that several hundred thousand of microscopic polyester fibre fragments are discarded from every wash process involving polyester and blends of this. This finding applies to both commercial and domestic washes.

The obvious initial approach to reducing the effect on the environment of this enormous daily number of microparticles from laundering is by filtration. Yet to date LCN has only discovered one country, France, which has taken the very reasonable initial step of reducing this massive source of particles. This year LCN understands that every washing machine sold in France for domestic or industrial washing will be required to be fitted with a drain filter capable of removing the bulk of these micro-particles.

There are two very different groups of filters now on the market, one relying on a fine screen and the other on a hydrocyclone. The screen, relies on simple physical catchment; the hydro-cyclone embodies induction of high-speed rotation of the discharge, flinging the particles to the edge of the device for collection and ultimate removal. Both envisage periodic cleaning at approximately weekly intervals to maintain efficiency. This is deemed commercially viable and reflects the fact the total weekly volume of microplastic contamination is quite low – even several million microparticles do not represent very much fibre loss. The contamination is currently deemed suitable for normal disposal as nonhazardous domestic or commercial waste.

The Xeros organisation in the UK has spearheaded the hydro-cyclone and they have a successful unit on the market worldwide, which can be accommodated as original equipment into any standard washer design. There are several suppliers of simple filtration devices now on the market, most of which appear capable of installation as original equipment or of being retrofitted. It is interesting to note that when the French authorities commissioned testing of removal performance, prior to drafting their new law, the hydro-cyclone was reported to give the best removal, although most devices took out over 95% of the critical micro-particles (which is a promising start).

Recycling can also produce toxic chemicals

The appearance in recycled plastics of chemicals already known to be harmful was surprising, given the enormous reliance now placed on recycling to solve the build-up of plastic waste worldwide. More research is clearly needed to determine the full range of chemicals involved and the levels at which these might pose future problems. This finding does not reduce the important role which maximum recycling will play, but it might flag up the need for purification of the recycled product. It could even reveal possibilities for the collection and sale of valuable by-products.

Degradation of plastic contamination

Several research laboratories worldwide have started trials on potentially economic methods for breaking down plastic waste (including the tiniest microplastic particles), because work has already shown that relying on natural degradation is insufficient. For example, polyester takes around 500 years to degrade. The most encouraging results have involved specific bacterial micro-organisms and some of these have shown remarkable results, including splitting long chain polymers back into the original monomers (offering the potential to use the monomers to recreate virgin plastic). One important piece of research has found a method not only of breaking down polyester, but also of doing this for polyester-cotton without degrading the cotton component (reference 5).

Early research on the use of bacteria found that heat energy was required to maintain the breakdown, which placed an unwelcome financial cost on the process. More recent work has discovered how to use bacteria from within the Arctic Circle to achieve degradation without the need for external heating (reference 6).

Development of novel plastics

There has also been success with novel plastics, which can be designed to be recycled readily into their original constituents (reference 7). Recycling is essentially designed into the construction of the novel plastic molecule to give an economic low-energy process with high efficiencies on the amount of original constituent recovered. However, when one looks at the time it has taken mankind to develop useful products (such as polyester fibre and polycotton textiles), the prospect of repeating these successes around a novel plastic does look somewhat daunting. Perhaps this makes reliance on replacement of current plastics with novel recyclable ones a longer-term project.

The way forward

Although achieving zero discharge of micro-plastic particles into our oceans might be desirable it is not realistic to reach such a goal immediately, even given the political will (which appears currently to be almost non-existent). An achievable goal might be to follow the lead set by France and legislate firstly for every new washing machine to be fitted with a suitable filter on the discharge to drain. When this is achieved might be possible to legislate for every older machine to be retrofitted. The cost per unit should be affordable and would be spread fairly evenly at one per household and only a few per laundry.

We do not yet know how important it will be to clean up the considerable tonnage of plastic micro-particles which we have allowed to accumulate in our oceans and become distributed so widely. However, it is probable that every resident in the developed world has already accumulated multiple contamination of several of their internal organs with micro-plastic particles, so the research into the probable effects of this should take an appropriate (high) priority for the next five years.

We live in a world which is struggling to counter the threat of climate change, and which is still studying lessons from our lack of preparedness for a pandemic, but failure to deal with a build-up of micro-plastic contamination in our oceans and in our bodies could mean we face consequences of just the same order. How could we have we allowed this to happen?

Reader query: fire insurance

Richard Neale responds to a reader alert on fire insurance policies, analysing the problem so you don’t get burned

LCNi recently received an e-mail:with a serious warning about fire insurance.

“Dear Kathy Your name was provided by one of your readers who runs several commercial laundries in Great Britain. He thought your readers should be alerted to a problem that lies hidden within their insurance policy document and only surfaces when it is too late.

“ I have attached a notification that fully explains the problem. The fire that I refer to is one of several that I have investigated over many years of investigating fire insurance claims. This would rate among the worst examples of how an insurance company inserts a condition on a commercial and business policy but does not explain what they require from their policy holder to fulfil this policy condition.

“It was only through constant pressure that I obtained from a leading Lloyds insurer a definition of this condition within the policy, and I would like all commercial laundries to be aware of this and protect themselves from a similar experience that could effectively ruin their business.”

Background to laundry fires

The regular occurrence of laundry fires is very depressing and the fact that there are now not that many is small comfort if you are the owner or general manager of a successful business, and you are awakened at 3 o’clock in the morning by the police or fire service to be told that your operation is blazing. You face not only the awful task of raking through the ruins to see what, if anything, is salvageable, but you have a crowd of disappointed customers all expecting essential deliveries. You are pitched straight into a frantic series of phone calls to your competitors to organise their immediate help, together with making urgent orders for the textiles destroyed in the blaze.

If you are already stretched financially, you then have the unenviable task of seeking immediate loans from you bank at an affordable rate of interest, followed immediately by negotiations with your insurers. Unfortunately, this last is not always straightforward, because even major insurance companies will reject a claim if they believe that you have not honoured your part of the contract, which might be buried in small print.

History

Although the UK Home Office receives a typical 3,000 laundry fires per year reported, most do not result in excessive financial loss or deaths. Fires in small commercial laundries can be swiftly extinguished if they break out during working hours, but if the laundry closes overnight when no-one is present, then even a small blaze rapidly becomes uncontrollable.

The same applies to large laundries, but the consequences are much more dramatic, with blazing infernos making headline news. Typical claims are often upwards of £5m, so if the claim can be legitimately refused it spells disaster for the laundry business. One or two claims per year still exceed £5m and the frequency appears stubbornly persistent.

Both insurer demands and government legislation now require every business to be equipped with in-date fire extinguishers for staff trained to use them, but as far as laundries are concerned, the requirement is only borderline adequate. It has been noted in at least one experiment, with cigarette lighters deliberately left in workwear pockets entering a tunnel finisher and every spare operative standing by with an extinguisher, the staff only just managed to put out the resulting blaze.

Where laundries equipped with sprinkler systems have experienced a fire, the damage has usually been much less, but sprinklers are no substitute for fire prevention. The problem has been identification of the reasons for fires which break out in the middle of the night, when the laundry is completely and safely shut down. The recurring mystery is what causes this socalled ‘spontaneous combustion’ why does it cause such widespread destruction and how can it be foreseen and prevented?

Probable causes of spontaneous combustion

Most launderers are familiar with the normal fire risks from careless smokers and from electrical short circuits. These risks are the same as in any office building or industrial factory and there is no reason for them to make laundries any more unsafe than premises in other sectors. They are countered by good staff training and supervision and by regular safety checks and effective risk assessment.

These measures appear to have had little effect on incidences of spontaneous combustion. There has to be a reason why laundries experience fires that break out in the middle of the night, when the laundry has been empty and quiet for several hours. One clue is the frequency with which a chief fire officer has found the probable seat of the fire to be in the finished goods area. At least one laundry with CCTV has footage showing a pile of clean napkins appearing to explode to initiate the fire, flinging flaming textiles in all directions and enabling rapid propagation. One laundry in a small factory unit experienced two fires in the finished goods area in a short period, but the fires did not spread to the rest of the premises.

Their solution was to separate out the piles of freshly ironed or tumbled work before closing for the night. They still got the occasional fire (possibly about once a year thereafter) but the damage was limited to just one pile of clean goods, and they managed to deal with the resulting smell.

One on-premises laundry in a residential institution experienced four fires over the space of less than a month. Investigation revealed changes in staff (with an inexperienced new team) and strong suspicion regarding accuracy of manual detergent dosing and wash cycle selection on the washer extractors used.

Fire insurance policy alert

Fires in commercial laundries are a risk that Insurance Companies will cover, subject to special conditions that are found within the policy wording. These clauses are called Conditions Precedent. A typical wording incorporated in the Policy Schedule of a Commercial Combined Insurance Policy is:

Drycleaning and Laundering: Condition Precedent

All items which have undergone any process at the premises are allowed to individually cool fully before piling stacking or packaging.

This condition was inserted due to the risk of fires from spontaneous combustion. It particularly applies to towels that have been used in Spas and Health Clubs, where organicoils are used. Even with the best wash, remnants of the oils remain in the towels and given the right circumstances spontaneous combustion occurs, and a fire ensues.

A recent fire in a commercial laundry in the UK caused £1million-worth of damage, although the laundry followed a procedure that is standard within the industry. The insurer denied liability as it claimed the laundry had not complied with the condition precedent. The procedure followed by the laundry had not altered for 20 years. At the end of the drying process there was a preset cooling cycle. The operator then opened the dryer door for10 minutes before removing the towels. This operator had over 18 years’ experience and did not wear gloves, which enabled him to check the towels for dryness and c olness.

When this leading Lloyds Syndicate was asked to explain the procedure that they requiredtheir policyholder to follow to ensure compliance with the condition, their reply was impractical and unworkable:

“Insurers would expect that in order to comply with policy terms, each item should be separately removed (or removed and separated) from the machine, checked for heat, left to cool individually (e.g. by hanging the items on a line or rack, or laying out the items on shelving) and then stored appropriately.”

If you have a policy which includes a cool down condition which cannot be followed practically, contact your broker urgently because according to the leading Lloyds Underwriter your Insurance Policy will not respond in the event of a similar type of fire.

Conslusion based on work so far

- The most likely cause of spontaneous combustion is an exothermic chemical oxidation reaction between unremoved contamination and the oxygen in the aA, leading to an exponential rise in textile temperature until the auto-ignition point is reached. The key is to ensure that decontamination is essentially complete.

- Reduction of the risk of this happening after laundering requires good detergency together with an emulsifier designed to cope with the full range of HLB (hydrophilic-lipophilic balance) values for all contaminants likely to be present. Many common emulsifiers do not do this, but leading chemicals suppliers worldwide are well able to offer detergents and broad range emulsifiers, with appropriate dosages, stage times and temperatures which reduce the risk to a very low level. The critical classifications include garage work, spa textiles, and food work carrying fatty proteins, but this list is by no means complete. Spontaneous combustion appears to be possible on almost any contract.

- Risk reduction during and after drycleaning demands a searching solvent with a high KB (kauri-butanol) value, together with the right detergent and appropriate dosages, stage times and temperatures using a two-bath process.

- Any residual risk can then be reduced further by ensuring a thorough cooldown after tumble drying or heat finishing, but this is no substitute for proper decontamination in the first place.

- Programming tumblers always to cool down to below 40C (for example) at end of cycle can be achieved with modern programmable dryers, and this would be a much better alternative to the one described in the reader query (which might be regarded as hopelessly out of date and certainly impractical). One might argue that any such condition of a policy is so impractical and unfair as to be set aside in any dispute, but that is beyond the scope of this article.