Texcare 2024 turned in its figures for the show which ran 6-9 November 2024 in Hall 8 of the massive Messe Frankfurt exhibition complex in Frankfurt am Main. Show organiser Messe Frankfurt has reported an exceptionally high level of international participation and top marks from the participants. Three hundred and five companies from 32 countries presented their innovations in automation and energy efficiency. About 15,500 visitors from 122 countries came to Frankfurt.

There was a palpable buzz around the stands and at the many seminars taking place during the show that was testament to the justifiable confidence of the organiser’s claims ahead of the event that this show was going to be special. It really was.

According to Messe Frankfurt, 98% of visitors were satisfied to extremely satisfied with what Texcare had to offer, and 97% said they had achieved their goals for the trade fair. Visitors from a total of 122 countries came to the leading trade fair. The top ten visitor countries were: Germany, Italy, the Netherlands, France, Spain, Great Britain, Poland, Belgium, Greece and Switzerland. The most important visitor countries from outside Europe were the USA, China and Australia. The degree of internationality was around 70% for visitors and 72% for exhibitors. The main areas of interest for visitors were machinery, equipment and components for washing, cleaning, drying and finishing textiles, as well as for energy generation, energy saving, recycling, environmental and water technology. Texcare took place over four days, with a new sequence of days from Wednesday to Saturday. Exhibiting companies at Texcare 2024 and their products can be viewed 365 days a year in the Texcare Contactor: www.texcare.com/contactor. You can find more comment from the organiser at https://www.laundryandcleaningnews.com/news/texcares-triumphant-return-signalsa-bright-future-for-the-textile-careindustry/?cf-view

Jensen-Group looked back over a successful four days at the show, where the company had a busy time on its 1,600 m2 stand. The booth was packed with advances in laundry automation, robotics, chemicalfree wash disinfection, a new superefficient mechanical handling system and a high-speed garment loader along with other new equipment and solutions. The solutions on the stand fully supported Jensen’s avowed mission to, along with laundry businesses, create the future of laundry automation and shape the industry in a sustainable way.

According to Nicolas Gostony, Jensen’s head of marketing: “We showcased various innovative solutions that captured our visitors’ interest, leading to meaningful conversations. Our automated soiled side sorting systems, innovative washroom technologies as well as finishing solutions for flat linen, towels, workwear, and mats were all highly appreciated. In partnership with Inwatec, we presented the latest advancements in laundry automation, receiving positive responses from our customers and partners.”

A standout feature, says Gostony, was the automatic soiled side sorting system with camera technology and AI, showcased in collaboration with Inwatec. “This solution sets a new benchmark for efficiency and ergonomics and is anticipated to become the future standard in every laundry. Over 150 automatic sorting systems have already been successfully installed worldwide, confirming that as suppliers, we offer expertise and innovation leadership unique to our industry.”

Hygiene and efficiency were key topics in the washroom area. UVClean, the chemicalfree disinfection method for the double drum section of tunnel washers, was recently granted a patent as well as a hygiene certificate from the renowned German Schubert Hygiene Institute. With UVClean, 90% of the bacteria in the double drum is eliminated after just 30 minutes, going up to 99.9% after 90 minutes. Jensen tunnel washers also claim to feature the shortest transfer times in the industry, thanks to the open drum design without scoops.

The entire batch is transported to the next compartment in just four seconds by the Archimedean helix. The updated and fresh look of the machine visualisation was very well received by all clients. Every machine can be operated from any other PPC in the wash line thanks to compound redundancy (the ability to operate any machine in the wash line from any PPC). For example, if one PPC fails or becomes inaccessible, another PPC can take over its role. This duplication ensures continuous operation without downtime.

For material handling, Jensen introduced the new RailExpress, a streamlined software solution for full functional control of basic to moderately complex Futurail systems. Laundries can continue to benefit from Futurail’s well-known hardware strengths, like durability, longevity, and increased uptime with a control system that offers excellent value for money. The AutoCalibration feature for Futurail’s sorting bins with its single push button calibration ensures a steady, correct loading of the tunnel washers – with no underloading and no overloading, which can result in incorrect dosing of chemicals, water consumption, and energy. This can significantly contribute to a laundry’s carbon footprint and will soon become an industry standard.

Just in time for Texcare, the new MetriV loading station for garments was launched, a streamlined entry-level workstation that combines a robust design with impressive speed and high capacity. For comparison, it was showcased alongside Jensen’s MetriQ, a high-end loading station featuring builtin comfort and the unique buttons-to-thefront design. “The MetriQ is considered the most ergonomic loading station for garments in the industry,” said Gostony.

“Other exciting innovations on display were our range of flexible towel feeding systems, including manual, automated and even fully automated solutions: In the automated solution, a THOR.Towel unit separated and transferred towels to an operator who can speed up the feeding process by up to 83%, achieving 1100 pieces/hour (PPOH) compared to 600 PPOH in a fully manual process. The THOR.Towel feeder is particularly popular in Japan, where workforce is scarce, and this exhibition marks the solution’s first appearance at an exhibition.

The BLIZZ robot for fully automated towel feeding comes with a redesign that allows for more buffer inside the machine, ensuring a stable performance throughout the day – handling 500 small and large pieces in mixed batches.

A significant highlight at the booth were the three state-of-the art flatwork finishing lines, all connected to an impressive Jenway transport and storage system. The Jenway conveyor system equipped with trackand- trace and various sorting and eject technologies connected three ironer lines with Express Pro and KliQ feeders followed by our new Silverline folder with reversing conveyors and space-saving inline stackers. Demonstrations at the booth showed a peak production of 2000 sheets per hour in two lanes on the new Express Pro feeder thanks to four feeding stations for fast cornerless feeding.

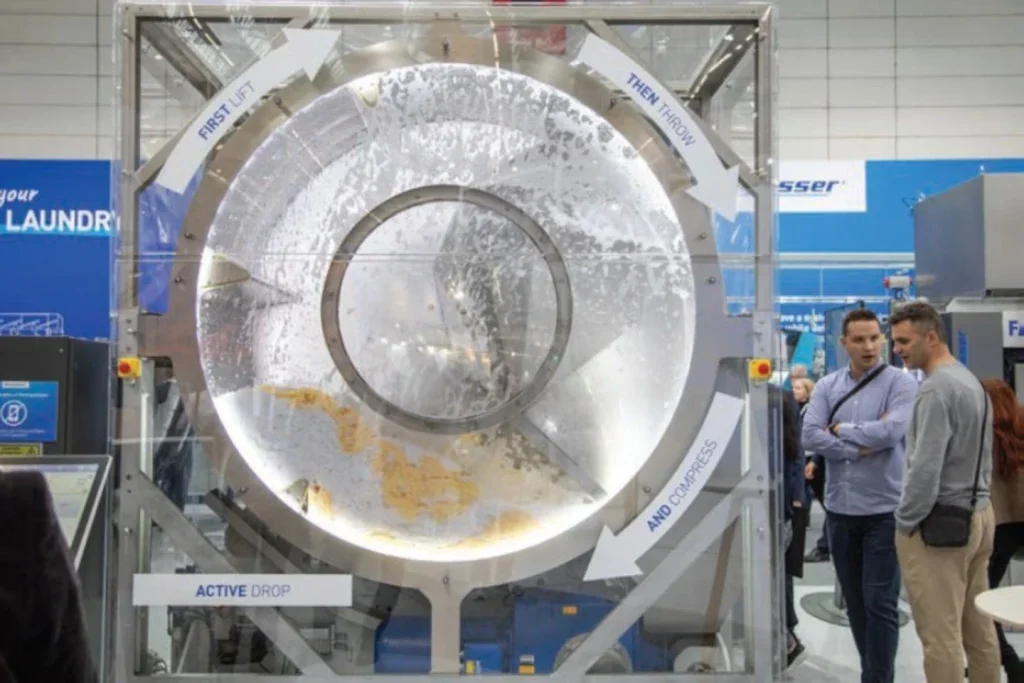

‘Let’s Create Your Next Level Laundry’, was the message from Kannegiesser which presented its latest solutions, addressing key challenges in the laundry industry with practical innovations in automation, robotics, ergonomics, and sustainability. Kannegiesser demonstrated how tailored solutions can help laundries enhance efficiency, sustainability, and overall service quality.

“The laundry industry is at a critical juncture where the need for efficiency, sustainability, and quality is more pressing than ever,” said Tina Kannegiesser, CEO of Kannegiesser. “At Texcare, our focus was on delivering the next level of technology and services to empower our customers to navigate these challenges successfully.”

The future of laundry

Next level automation: Responding to the growing demand for automation as a solution to labour shortages and the need for efficient production processes, Kannegiesser unveiled new automation and robotics solutions, enhancing productivity across laundry operations. As Kannegiesser’s Jennifer Frentrup told LCNi: “Robots are great for productivity and for tackling the labour shortage. They don’t need to go to lunch or have coffee breaks – they have no natural bodily functions to attend to. All they require is some occasional maintenance.” Maybe eventually by another robot.

Next level sorting: How about sorting a la carte? Do you wish to sort by article size? Colour? Or by RFID? Kannegiesser says it is setting new standards in sorting technology. From sorting on the soiled and clean sides to machine sorting based on size, colour, barcode, and RFID technology, these solutions offer flexibility and precision, aligning with the specific processes of each laundry operation.

Next level ergonomics: “The use of robotics will increase in laundries but we will still have manual labour for a long, long time,” said Frentrup. So, Kannegiesser has prioritised ergonomic innovations that enhance both employee satisfaction and productivity.

Next level sustainability: Sustainability is now a critical demand in the laundry industry. Kannegiesser’s sustainable technologies reduce energy and water consumption, helping laundries cut operating costs and reduce their environmental impact.

As Frentrup explains: “We need solutions customised to individual laundries, large, small and diverse. We have to find the best solution and always a quality one.

“The core business for all laundries is washing and here we have the PowerTrans tunnel washer – deep cleaning but gentle on fabric. The Synchro Pro feeder with SwiftCare offers perfect alignment of the sheet and a little bit of slack when it is grabbed – that is a good thing as it doesn’t stretch the fabric thereby extending the life of the item.”

LCNi looked at the new EMR SynchroRemote feeder which Kannegiesser says offers 37% more feeding capacity than conventional feeders and 66% less grip needed on the sheet, therefore 25% less risk of wrist injuries as there is less physical stress when loading the item. The machine has been issued with independent ErgoCert Institution certification.

The dry work line can automatically fold, sort and stack laundry batches containing mixed towels from hotels and hospitals. It consists of the newly developed and fieldtested Robofeed RFT feeding robot and the Speedline XFM-SR folding machine. The Robofeed is equipped with the latest camera technology, which enables a servo-controlled gripper to recognise each individual piece, separate it and feed it to the folding machine at maximum speed.

Also on show was the X-loader hanger loader for the garment-hanging rail system. The loading station provides hangers quickly and without waiting time. It can also be continuously adjusted to any body size and is very easy to operate.

The X-Stream tunnel finisher has four modules in three, offering super efficiency. The new counterflow design saves time and energy. It works by juxtaposing cold and heat. The items enter the apparatus from the hottest end taking heat with them in the counterflow to the coldest point. It is a very efficient system.

Michael Harre, chief sales and service officer, added: “We are committed to developing tailor-made solutions that not only meet the current demands of the market but also future-proof our customers’ businesses. The innovations we present at Texcare highlight this commitment.”

After an eight-year hiatus, Tolon made a remarkable return to Texcare International 2024 with its biggest and most impressive booth to date. Tolon made sure it stood out with a bold new design featuring bright, balanced colours, emphasising the company’s signature orange, symbolising its vibrant energy and dynamism.

Since its last appearance at Texcare, Tolon has undergone a significant transformation as well. In 2016, it forged a strategic partnership with Jensen- Groupand this collaboration marked the beginning of a period of rapid growth and global expansion for Tolon.

Throughout the event, Tolon’s booth was a bustling hub of activity, attracting visitors from across the globe, including regions such as Brazil, Latin America, Australia, and beyond. The focus was on innovation and connection.

According to Tolon: “With a clear vision for the future, Tolon leaves Texcare 2024 energised and motivated, ready to build on the momentum of this successful event.

“Tolon’s impressive return to Texcare Expo was more than just a participation – it was a powerful statement of their ambition and vision for the industry. The company’s efforts and achievements at the event signal a promising future, one filled with innovation, growth, and strengthened relationships.”

Krebe Tippo has also been busy over the past eight years and for Texcare 2024 the company added a new size to its popular hardworking, hard wearing barrier washer range, which it re-imagined over the Covid years and “made all new inside”, and launched its HygioVisionTM hygienic monitoring software system.

Anja Uranjek, head of sales and marketing at Krebe Tippo told LCNi: “Krebe Tippo is concentrating its attention within the clean room market with quality, robust, heavy duty machines for heavy duty laundry needs. Our barrier washers are all produced to ISO clean room standards.”

Krebe Tippo is getting stronger in the clean room industry and presented a 90 kg capacity machine fully equipped for this very special niche. “A niche within a niche,” said Uranjek.

New solutions with the emphasis on barrier washing machine technology could also be seen on the stand along with a new product called HygioVision, a brand that represents several solutions for laundry optimisation with connectivity created to satisfy the highest global hygiene standards, explained Uranjek.

“All Krebe Tippo machines are designed to ensure the best quality of washing results with minimum consumption of water, detergent, and energy. Machine construction is robust and stable, designed to ensure longevity of each and every part of the machine under heavy burdening.”

In 2022 Krebe Tippo launched its 516 Smart Drum concept where machines are equipped with RFID readers and a database to eliminate the risk of linen being lost or mixed.

According to Lapauw, the theme of its stand at Texcare, ‘Built on Tradition. Powered by Innovation’, speaks to the company’s commitment to quality and innovation. Lapauw is showcasing its ‘state-of-the-art’ ironing line designed for production and quality.

Thanks to innovations like true parallel heat flow within its chests, the IronMAX sets the benchmark in ironing performance, making it an indispensable tool for industrial laundries and applications where productivity count, said Lapauw.

Also on show was the Unix, Lapauw’s clamp feeding machine that combines optimal feeding quality with high speed. Meanwhile, the VS folder line combines space-saving design with automation, boosting productivity and operator comfort.

Valmet has long offered a complete range of high-quality technical textiles and accessories for laundry machinery with more 70 years of experience. Specified by the majority of the laundry machinery manufactures globally, Valmet is the mainstay for maintenance items for feeding and folding apparatus and ironers.

Milnor showed its Milrail system among other laundry solutions and reported stand vists by dealers and very happy customers.

CLMTexfinity, a dynamic joint venture between CLM and Texfinity, headquartered in Belgium, showcased its full range of advanced industrial laundry systems and introduce new innovations. Texcare marked a significant milestone for CLMTexfinity, solidifying its position as a trusted player in the European market, said the company.

CLMTexfinity introduced several new products, including the brand-new S.feed s Plus and the S.press MP (Medium Pressure). The S.feed Plus, an enhanced version of the S.feeder, significantly boosts efficiency by adding an intermediate buffer position between the feeding and spreading clamps. This innovation reduces the number of operators required while increasing throughput. The S.press MP is a robust and durable press featuring a heavy-duty structure and a reliable hydraulic cooling system, setting a new benchmark for industrial laundries.

“The feedback from visitors and clients was overwhelmingly positive. Customers particularly appreciated the sturdy build quality of the machines and CLMTexfinity’s transparent spare parts strategy. The company’s open approach, sourcing commonly used components from wellknown and accessible suppliers, not only ensures reliability and availability but also results in significantly lower costs for spare parts. This distinctive strategy gives customers confidence in their investment and sets CLMTexfinity apart from other industry players,” says the company.

“Texcare 2024 has opened doors for us,” said Reinoud Pijpops, owner of CLMTexfinity. “We not only strengthened existing relationships but also made promising new connections. It’s clear that the market is ready for CLMTexfinity, and we are ready to embrace that responsibility. CLMTexfinity aims to continue playing a significant role in the industrial laundry sector in Europe. The company looks forward to the future with confidence and is determined to grow and meet the evolving needs of its customers in the years to come.

Eduard Colomer, laundry export director for Domus says: “Our stand really caught people’s attention, showing off everything we offer, from self-service solutions and machines for small businesses to advanced equipment for OPL and industrial laundries. Each area of our stand was set up to give visitors an up-close look at our full range of Domus products, letting them experience our technology and laundry solutions first hand.”

DomusConnect IoT technology (connecting everyday devices to the internet) allows Domus machines to connect online, gathering key data to improve washing and drying times while managing the business remotely. This gives users more control, offering detailed reports on production, cycles, consumption, revenue, and more. It also ensures high-quality processes, guaranteeing hygiene and disinfection in every wash and dry cycle. “Additionally, our new LEMS (Laundry Efficiency Management System) collects data from various counters and centralises it, generating useful metrics for industrial or self-service laundries. Once the data is gathered, it is transmitted via IoT to DomusConnect. The LEMS system enables real-time tracking of water, gas, and electricity usage, and creates detailed, custom reports through DomusConnect. With this system, Domus shows its commitment to innovation and efficiency, providing a complete solution that turns your laundry into an Ecosmart laundry,” said Andreu Arrom, Latin and Spanish laundry director at Domus.

Ecovolution is a new range of energysaving products from Domus loaded with the latest technology, explained Arrom, with its major benefits listed below:

Water: Our goal is to use water efficiently. Our washing machines are designed for better programming and optimisation, and come with ECOTANK reservoirs for water recovery.

Energy: Saving energy is crucial in any laundry, which is why our machines are specially built to maximise energy efficiency.

Chemicals: Our washing machines are designed to use chemicals more precisely, which means greater savings and better care for garments.

The Ecotank XL water recovery systems, she adds are perfect for front-loading washers as well as sanitary barrier washers as they help create a more sustainable and efficient laundry, allowing water recovery and promoting environmental care.

Domus also offers a wide range of machinery tailored to any self-service business. With constant advancements in products and technology, we’ve introduced efficient solutions like the Domus Laundry app, the Domus Laundry Kiosk payment system, and the new Clean&Move container.

The new Domus Laundry Kiosk central pay allows self-service laundries to offer the best contactless payment solution, linked to the DomusConnect platform and compatible with the Domus Laundry app. Customers can pay with their mobile or contactless card.

Owners can monitor operations, view graphs, manage multimedia content, set pricing plans, offer discounts and promotions, and check the status of the kiosk remotely. This new payment hub improves the user experience with simple and intuitive operations, lowers management costs, and provides security for both users and owners.

Meanwhile, according to Laura Planas, global digital brand manager at Girbau, Texcare was a great experience, offering time to connect with customers and gather insights about industry trends, needs and future perspective.” The Girbau booth was full of people, especially interested in the Genius washer, Sortech – Girbau’s latest solution for automating the sorting of soiled linen – along with other sustainable solutions. The company’s paper banding machine, microfibres filter and water recovery systems also attracted attention.

Through cutting-edge RFID technology, Sortech individually identifies garments, reads their chips, and automatically categorises them, offering a highly configurable system adaptable to various productivities and spaces.

Improvements to the Genius series, a connected washer with the fastest cycle on the market, enabling up to 15 cycles per day, boosting your productivity like never before. Its robust design, with 27% fewer repairs than competitors, according to Girbau, ensures continuous operation. 24/7 remote monitoring and control through the Remote Machine Program Editor, allows management of productivity and efficiency from anywhere.

Girbau’s Zero Water solutions allow the recovery of up to 85% of water, saving money, guaranteeing efficiency, and actively contributing to the environmental protection.

Also attracting attention was the new PRT60 turbo press which can process up to 2,400 kg of linen per hour thanks to its turbo cycle time of just 60 seconds combined with a 30-second press time. By increasing pressing time to extract more water and reduce drying time, launderers can save up to 2.5 kWh per batch of linen.

“It was clear that something’s changing around the industry and laundries are putting effort to be more efficient and sustainable in their operations. We received good feedback about our presentations in the booth and our sustainability officer, Joan Vilaseca, participated in a Sustainability Roundtable along with EcoLab and Jensen, discussing the challenges and solutions for advancing energy recovery and achieving carbon neutrality by 2050,” says Planas.

– Christeyns, a global leader in textile care solutions, meanwhile prented concepts and technologies that it says redefine efficiency and sustainability in laundry operations. Rather than focusing on individual products, the company emphasised comprehensive solutions under its new ‘WOW – We Optimise Wisely’ initiative, reflecting Christeyns’ mission to enhance washing, energy, and water management processes.

Christeyns highlighted several key innovations, including EPIC, its innovative wash concept boosted by enzyme technology ensuring high efficiency,which helps laundries meet strict environmental regulations while reducing wastewater costs. Complementing this is the HydRO water treatment and recovery technology, developed in partnership with Veride. With over 30 systems installed across Europe, HydRO enables clients to recycle at least 80% of their process water, resulting in a savings of over 100 million liters in 2023 alone.

Enhanced energy management capabilities afre made possible through the integration of TBR’s expertise, particularly in heat pump technology, to deliver more eco-friendly process solutions.

HydRO Technology is a plug-andplay approach to water recycling, offering on-site water treatment and reuse through HydRO Technology. This system, prominently displayed outdoors underscored Christeyns’ commitment to closing the water management loop.

“Our solutions at Texcare demonstrate our vision for the future of the textile care industry,” said Alain Bostoen, CEO. “We’re proud to lead with innovations that meet our clients’ needs for efficiency, sustainability, and cost reduction.”

Adding a creative touch, Christeyns delighted visitors with HydRO Gin – a unique gin crafted using recycled water from laundry processes. This highlight effectively demonstrated the efficacy of HydRO technology, says the company.

Ecolab emphasised its commitment to partnering laundry businesses in relationships that are much more than a supplier/customer link-up. Hence it has developed special products for special needs. Basically it is a ‘wash design consultant’ concentrating far beyond the provision of wash chemicals to devising solutions that also deliver on sustainble goals with best water management, energy recovery and low temperature washing that extends the life of textiles. Ecolab promises to build ‘tailor made suites’ on individual journeys with laundry businesses.

Automatic dosing systems designer and manufacturer Brightwell has unveiled its groundbreaking Multiplex range of extremely durable scalable, automated IoT dosing systems, designed and engineered to enhance chemicals delivery for largescale industrial laundry operations. Aimed at a wide range of laundry sizes, Multiplex delivers chemicals to multiple machines with a choice of four versatile models to provide precise dosing for anywhere between 4 to 12 washer extractors.