As the big day approaches, that is the opening day of Texcare 2024 , after an absence of eight years, a wave of anticipation is beginning to swell about the developments we are going to see there. Messe Frankfurt will host the event over 6-9 November and is looking forward to welcoming an influx of industry professionals from all over the world.

Every four years (except when a pandemic raise its ugly head), Texcare International in Frankfurt am Main is the focal point of the global laundry, cleaning and textile services industry. Suppliers and service providers have a platform for their innovations. For visitors, it is a source of inspiration and a genuine networking platform.

This year the focus is on AI, automation, digitalisation, reducing labour and energy costs and sustainability across all textile care disciplines in products and services. A full programmesof seminars will also help to push the message home that it is time to step up and embrace a new way of working – if businesses want to succeed in a changing world then they must change too.

Energy

Commercial laundries make up an energy-intensive business sector with energy accounting for around 15% of total costs and with process heat making up the lion’s share of that figure. Against a backdrop of continuing high energy costs and the challenge of global warming, energy-saving measures and the move away from fossil fuels are of increasing importance for laundries. Hence, all machine and equipment manufacturers are working on the development of concepts that optimise the use of resources and reduce carbon dioxide emissions.

Water is key to cutting costs

Recycling process water is nothing new in the laundry business. However, concepts for recycling pressing water, filtered rinsing and process water and the use of cooling water from the drycleaning machine are constantly being improved, which further reduces the amount of fresh water used.

Reducing energy consumption

Manufacturers of laundry and drycleaning machines, as well as finishing appliances, focus on technology with an optimum efficiency classification: such machines ensure the best possible water extraction and low residual moisture in the laundry so it can be dried quickly and efficiently. Plant manufacturers use new materials, e.g. ceramics and carbon steel, to reduce ironer gas consumption. They also utilise heat-pump technology and generate hot water by means of solar energy. Modern machines are also equipped with special coatings that stop dry, energy-absorbing fluff from adhering to the various surfaces. New technologies improve evaporation performance or improve solvent distillation by preventing boil-over, measuring turbidity or filtration.

Increasingly, the energy contained in vapour is also being harnessed: technologies such as low-pressure vapour recovery systems ‘recycle’ energy from steam to generate process heat.

The system as a whole

Reducing the resources consumed by a textile care business cannot be achieved by implementing isolated measures, but only as part of the overall system in which all processes are intertwined: waiting times at machines, idle times and poor occupancy rates result in unnecessary energy losses. In an energy-optimised laundry, however, every item is in the right place at the right time.

Additionally, management information systems make it possible to precisely analyse energy consumption in all parts of the laundry and provide a solid basis for modifying processes or making investment decisions.

Detergents and processes

The detergent industry also uses processes and products to promote the optimal utilisation of resources in laundries. Low-temperature disinfection processes, which achieve a listing with the Robert Koch Institute (RKI) and the Association for Applied Hygiene (VAH) at 40°C, can significantly reduce the cost of process heat. In the meantime, however, a new benchmark has been established at 50°C for disinfection washing.

ETSA involvement

The European Textile Services Association (ETSA), in its 30th anniversary year, says: “ETSA is excited to announce its participation in Texcare International 2024, the industry’s leading worldwide gathering for textile care. Texcare is known for being the hub for innovation, connections, and idea sharing in the drycleaning, laundry, and textile services industries.

ETSA will participate by organising a panel discussion on the important topic of textile recycling. This panel discussion will centre on the most recent developments and difficulties in recycling methods, eco-friendly inventions, and the prospects for circular economy models in the textile sector. Considering the increasing significance of environmental responsibility and sustainability, this talk is sure to be one of the event’s highlights. Before the event, we will disseminate further information on this.

Keep checking back for further information regarding the exact day and hour of the ETSA panel at Texcare 2024, and the location of the ETSA booth.

Early bird preview: Who will be there?

In this preview we catch up with some of the exhibitors who have already, so to speak, laid out their stalls ahead of the game. In no particular order and as the news came in, we have heard from:

MIP Europe

Hall 18, stand H64

MIP Europe will be showcasing its range of bedding, laundry solutions, continence care, apparel and more for healthcare businesses. MIP is a global supplier and engineering expert of textile solutions and was founded in Canada ore than 40 years ago. Originally MIP manufactured and supplied the first adult reusable briefs to the healthcare industry. Today, MIP has a broad textile offering from laundry solutions to bedding, continence care and apparel. Products are distributed to over 30 countries around the world, from offices in the United Kingdom, Canada, Germany and the United States.

Experience MIP’s showcase brands at Texcare International such as the SleepKnit Bedding System, a unique knitted sheet design with multi-directional stretch which., Unlike conventional woven sheets , tne sheet will fit a wide number of mattress sizes and with the benefit of being latex free/elastic free. SleepKnit is designed to enhance the laundry process due to efficient drying times reducing energy consumption, and its no folding or ironing properties creating further time and labour efficiencies.

Also featured on the stand will be Fusion, the latest innovation in bedpad technology. Using patented design, Fusion is a fused, unquilted bed pad that wicks moisture away from the patients skin and minimises the potential for pressure points.

The company’s Comfort Line Scrubs. Will also be there for visitors to inspect.

Jensen

Hall 8, Stand

Join the experts at the JENSEN booth or an insightful exploration into the latest advancements in robotics, smart technologies, and materials handling solutions, transforming heavy-duty laundries. Jensen invites visitors to explore its diverse product portfolio, from standalone machines to seamlessly integrated, highly automated solutions handling large volumes. For every market segment, automation requirement, and capacity, Jensen has a solution to fit.

Jensen says:

- Witness three cutting-edge finishing lines equipped with state-of-the-art feeding and folding technology, all linked by the peak of laundry automation – the Jenway automatic transport and storage system.

- Experience our renowned towel feeder, part of our towel finishing showcase in three automation levels that tailor to individual needs: from ergonomic manual operation to a hybrid solution with automatic towel delivery, and finally, fully automated with the BLIZZ robot.

- Explore a section dedicated entirely to our offering for mat laundries, including a highly productive and customizable roll-through mat roll machine.

- Exclusive to our booth, experience the superstars for each washroom section: Our tunnel washer has the shortest transfer times in the industry and leads to substantial savings in each laundry operation. Maximum performance defines our water extraction technology as well as our new XR dryer, with remarkable time and energy savings.

- Visit our booth to witness an automated handling and sorting line featuring ergonomic loading stations, along with the renowned Fox – a true workhorse folding machine – demonstrating how automation can revolutionize garment handling.

- Examine two innovative approaches to soil sorting – because we all should get it right from the start: an upgraded Futurail solution and a fully automated robotics solution utilizing camera technology and AI.

There is even more to come: Stay tuned as we unveil additional exhibits and exciting details in the coming weeks, says Jensen.

BÖWE Textile Cleaning Systems

Hall 8, Booth G22

Based in South-West Germany in the Black One of the highlights on the booth will be the new BÖWE shirt press SP22, with its cycle time of just 10 seconds per shirt, which is unique in the industry. Equipped with a large steam radiator, fan, and an innovative heat recycling system, the SP22 also features newly designed condensate traps with no moving parts, ensuring durability and efficiency. Itproduces a perfectly pressed shirt using only 370W of energy. Additional product features include Teflon-coated press heads to prevent shiny spots on dark shirts and an adjustable sleeve height.

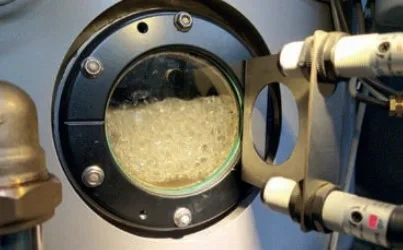

The new global innovation – the Böwe overboil protection for distillations (see illustration below). This breakthrough uses a photoelectric sensor that monitors the surface of the liquid in the distillation during the distillation process. If there is increased bubble formation, the sensor detects this situation and automatically breaks the vacuum for a short time. This leads to an increase in the boiling point and a collapse of the foam head. Black-over and dirt transfer are thus prevented.

From the Perc and Multisolvent ranges, the latest technology includes the special Black Forest Edition made of stainless steel and with cataphoresis coatings.

Visitors can also see the latest development—a wear-free steam trap made entirely of stainless steel, without mechanical moving parts. This steam trap offers a 10-year warranty, approximately 15% steam savings, and delivers 3-4°C higher temperatures at press heads and steam radiators.

The new shirt press, former, pant press, and ironing table with infrared-controlled special LED lights to detect wrinkles and spots more quickly. Additional features such as an auto-start function when lifting the iron, up-steam, and pneumatic height adjustment make these machines a valuable upgrade for any operation.

Alliance Laundry Systems

Hall 8, stand E90

Alliance Laundry Systems will be presenting what is describes as gamechanging energy-saving solutions during Texcare International.

“Expectations at Alliance are high for this edition, as Texcare did not take place in 2020 due to Covid restrictions,” said Jean-Baptiste Vandamme, Alliance’s vice president of sales for Europe. “The laundry industry will therefore gather for the first time in eight years in Frankfurt, so we expect a very busy four-day event. Preparations are currently in full swing.”

The Alliance booth promises a diverse range of products from its top European brands – Primus and IPSO. This year’s show theme is “Innovate to Sustain,” which emphasises the company’s dedication to innovation.

The highlight of the booth will be the launch of a new range of Europeanbuilt commercial tumblers, offering improvements in terms of energy use, efficiency, and connectivity.

According to Tijs Denuwelaere, Alliance marketing manager for EMEAI, Alliance will elevate the way it presents its products and technologies to the next level. “We are developing a series of digital experiences, which will allow visitors to discover benefits in an interactive way. Very exciting.”

Christeyns

Hall 8, stand E50

With nearly 80 years of experience and over 500 professionals in textile care, Christeyns has established itself as a key player in the industry. Christeyns will showcase its expertise under the slogan: ‘We can wash them all – family of experts since 1946’.

CEO Alain Bostoen emphasises: “Our 500 experts empower customers worldwide with solutions that enhance laundry operations and reduce costs.” Whether it’s healthcare or hospitality linen, workwear or delicate textiles, Christeyns has the expertise to deliver outstanding results.

What truly distinguishes Christeyns is its team—a “family of experts”—dedicated to supporting customers with sustainable initiatives that drive cost efficiency. With the patented EPIC detergency system their experts help laundries meet discharge standards and reduce wastewater costs.

“Our commitment also drives us to continually invest in water- and energysaving technologies,” continues Bostoen. Partnering with Veride, an international expert in water reuse, Christeyns has already installed over 30 plug-and-play HydRO systems across Europe, allowing laundries to reuse at least 80% of their process water.

“In 2023, we successfully saved more than 100 million litres of water at newly acquired customer sites. The success is monumental, but our vision for 2024 is even more ambitious—we aim to double this impactful conservation effort,” highlights Alain Bostoen.

Christeyns has further expanded its expertise by acquiring engineering company TBR, adding heat-pump technology to its portfolio.

Stahl

Hall 8, Stand B90

STAHL is recognised worldwide for its high quality made in Germany. With industrial laundry washing machines, laundry dryers, flatwork ironers, folding machines and accessories, Stahl covers the complete portfolio of laundry technology for professional use.

The high-spin soft mounted Atoll industrial washing machine is a popular classic and is suitable for all textiles and applications. Stahl has expanded the series to include the Atoll 650 and 850. In addition to these two new products, the new generation of the Atoll 180 will be presented. The manufacturer has also added to its range of energy-saving laundry dryers: The T 354 and T236 models have been further developed and the T 236 is now available with a new heating mode without exhaust air.

Another highlight is the compact heated roll ironer, which has been added to the range of ironers. The heated roll ironer is easy to operate, requires little space and is particularly suitable for small businesses. The manufacturer, which is actually known for its powerful large ironers, is thus closing the gap in its range of compact appliances.

Stahl will also be focusing on the new generation of the Servant laundry feeding machine, which enables laundries to feed flat linen into Stahl flatwork ironers more economically. Stahl has also made technical advances to its folding machines and will be presenting the new generation of the Starfold and Kombifold.

The innovative FREEpro microprocessor control system is now available for all Stahl appliances and has received a major software update.

Danube

Hall 8

Danube offers a diverse array of barrier washers for cleanrooms with a load capacity ranging between 16 to 70 kg, with electric, steam or dual heating.

“The range of cleanroom tumble dryers with capacities ranging from 11 to 80 kg, also offer a long list of options and are produced for each client upon order, with a long list of options designed for this type of installation, such as HEPA air filter, side fluff filter, AISI 304, 316, 316L stainless steel drum options, electropolished drum, moisture sensor, temperature probe, etc. to ensure that drying process is carried out with the cleanest air possible. Various sizes of HEPA filters are available depending on the requirements of each cleanroom. The drying process is also a very important part in such a site, and it should be emphasised that all our dryers can be configured to avoid cross-contamination with specific components accordingly’ says Danube’s Eduard Colomer..

Fintec

Hall 8, Stand F60

Fintec’s Claudia Pollauf and Andreas Ortolf, as the second generation of management, will show visitors the beauty paired with performance and robustness of its machines, says the company.

The core elements will be presented in a fully automatic system: starting from the loading station VarioLoad, over the transport system VarioTrans, through a gas heated model of the tunnel finisher VarioJet and then either to the VarioFold F 85 A or the newest member of our portfolio, the VarioFold mini. You will be led through the system via Fintec’s automatic hangers.

“We are happy to say, our founder, Heribert Ortolf, will also be part of our exhibition team. Ann-Kathrin Henkel, project manager and Rebaz Fouad, sales manager, complete the group,” says Fintec.

Kannegiesser

Hall 8

‘Let’s Create Your Next Level Laundry’, is the slogan as Kannegiesser is set to showcase its latest innovations in automation, robotics, ergonomic workstations, sustainable processes, and intelligent logistics at Texcare International 2024. Kannegiesser invites customers to work together to design tailored solutions that transform these challenges into opportunities, elevating laundry operations to the next level.

“The laundry industry is at a critical juncture where the need for efficiency, sustainability, and quality is more pressing than ever,” says Tina Kannegiesser, CEO of Kannegiesser.

“Our focus at Texcare is on delivering the next level of technology and services that enable our customers to navigate these challenges successfully.”

Michael Harre, chief sales and service officer, adds: “We are committed to developing tailor-made solutions that not only meet the current demands of the market but also future-proof our customers’ businesses. The innovations we present at Texcare will highlight this commitment.”

The Kannegiesser booth will also feature a dedicated Forum, where visitors can attend daily presentations showcasing the latest innovations and how Kannegiesser plans to create the ‘Next Level Laundry’ together with its partners of the textile service industry.

Barbanti

Hall 8, Stand C40

Barbanti will display some of its most popular machines, including Shirt Finisher 494 (the flagship machine in its latest version) with collar and cuff press 520.

Form finisher 467 and trouser topper TP65, ideal for both dry-cleaned and wetcleaned garments, now available with touchscreen control panel will a,lso be there.

Shirt finisher 440 offers high quality and high production at an attractive price whilke Barbanti says its universal finisher 451, is the only really ‘universal’ tensioning machine on the market.

Bagging machine I20 and spotting table SM20 are interesting alternatives to existing products and can be seen with vacuum/ blowing table TSFP, for high performance with maximum comfort.and more models.

All finishing machines are now available with different energy-saving devices and most models can be interconnected and managed by the new Barbanti platform CB Smart. Live demonstrations on all models and customized consultancy to finalize the best solutions for all needs.

Thermotex

Hall 8

German company Thermotex, which has been offering efficient over-all says its products can help to achieve safe, hygienic laundry cycle with optimised processes in laundry logistics and reduce costs in the long term.

Whether it’s flat laundry, workwear, leasing or private textiles, the requirements to identify textiles are constantly growing. Therefore, says Thermotex, correct marking is the foundation of successful laundry management. Pictured, its Palette UHF box, which, says the comany, is the most accurate single container scanner processing 500 itesm in 10 seconds.

REGISTER NOW FOR YOUR TICKET

https://texcare.messefrankfurt.com/frankfurt/en.html#registration

There are useful links from that page with handy tips on how to make the most of your visit including ‘How to get there’ instructions and where to stay in Frankfurt and the surrounding area. There is even information on local campsites for those who want to bring their own home with them. (There is actually room for motorhomes in Messe Frankfurt’s visitor car parks, albeit without electric or water hook up). You can also find tips and helpful links for you to make your evenings in Frankfurt after the trade fair closes as varied and inspiring as possible.