In the authors’ experience, failure to remove some of the most obvious stains tops the list of customer returns. While stains such as permanent marker and some dye stains cannot safely be removed, it is common to find simple stains that can literally be removed in seconds with the high-pressure water spray. We have also seen cleaners where over 20% of the garments on the stock rails had advice notes attached; in this instance it is very much a case of using stain tickets rather than the spotting table!

If you feel your turnover is below par, some root and branch research into your overall quality and customer service should reveal the areas that need to be addressed. Most cleaners believe that if their customer complaints are few and far between, then customers are satisfied. This is a dangerous assumption; there can be few of us who have not been out for an evening meal and have not nodded in approval when a waitress asked: “Is everything OK?” when in fact the food and service was mediocre. The truth of the matter is that many of us find complaining embarrassing and next time just go somewhere else. An honest, down-to-earth appraisal of your service might just solve the problem of a less than satisfactory turnover.

At the counter

Starting at the counter, careful inspection throughout production is the key to improving your performance and ‘getting it right first time’ and if it starts right there is a much better chance it will finish right. Good lighting is essential (minimum 500 lux at every stage if stains and physical damage are not to be missed. Every garment should be systematically examined all over with every pocket being checked internally. Any stains or physical damage should be discussed with the customer, and if necessary, a record made of damage. Some cleaners attach coloured spots to stains to help the operator. During busy periods when inspection might be limited, tell the customer you will contact them before cleaning if you find any issues. If you miss physical damage, it may be difficult to prove responsibility retrospectively.

Preparation for cleaning

It is the operator’s responsibility to systematically inspect every item, check care labels and pockets (if the linings have not been pulled out at the counter), and pre-spot soil/stains or remove stains before cleaning.

Some stains and particularly champagne, white wine and refreshments containing sugar can easily pass unnoticed by the customer and leave no visible trace when dry. Some cleaners use an ultraviolet lamp or device to help reveal this type of staining. This can be particularly helpful when dealing with wedding gowns and some high value items. Commonly known as developed stains, this type of ‘invisible’, water-based staining is not normally removed in drycleaning but when exposed to the heat of drying or finishing, the sugars may caramelise and leave a brownish stain that can prove difficult to remove, particularly on delicate fabrics such as chiffon. Wetcleaners are onto a winner here as, in most cases, this type of staining is removed in water-based cleaning processes. In addition, there are of course other stains such as absorbed food stains, which for one reason or another may not be noticed during reception and pre-spotting, but which are accentuated by drycleaning.

The problem for the drycleaner is that, if stains that were invisible during reception are missed during final inspection, the customer may be completely unaware that the garment was in fact stained, leading, in their mind, to the quite justified complaint that “these stains were not on when I brought it in”. As many cleaners will know to their cost, if this type of complaint is not handled sympathetically and professionally, it can develop into an acrimonious situation from which the cleaner is unlikely to emerge unscathed, particularly if witnessed by other customers waiting to be served. In addition, it is also possible that any low-level faint stains may go unnoticed by the customer and then gradually become masked by soiling only to be fully revealed after cleaning, once again leading to difficult conversations at the counter if missed during final inspection.

After cleaning

When items are removed from the machine, every garment should once again be systematically looked at all over, ideally on a table. This is critical as any stains that have developed in machine drying may not have become fully heat set, but if not removed at this stage may become much more difficult to remove, if exposed to any form of steam finishing. There will also be stains that may not have responded to pre-spotting, such as blood and egg (which contain albumin), that if exposed to the heat of finishing may be very difficult to remove or, on some fabrics such as pure silk, impossible to remove without risk of colour or fabric damage.

Pressing issues

Pressing and ironing can prove very frustrating when, having invested a lot of time and effort on a complex item, a stain is noticed. In the case of small stains, the finisher may feel they are of little significance and decide to turn a blind eye, knowing full well that if the garment is returned and re-cleaned, they will have to start the finishing process all over again.

As cleaners will know, there are also some stains that survive cleaning (and appear during drying or finishing) that can be “disappeared” by brushing or a light scratch with the fingernail. Bear in mind that this kind of stain may reappear later in storage, when small amounts of moisture from steam finishing evaporate. The same is true of other stains that if hydrated with the steam gun may disappear, only to reappear once again in storage.

Final inspection

To allow a variety of garments to be freely rotated at a convenient height, a light chain with suitably sized links is ideal. Final inspection is a difficult, repetitive and demanding task that requires an extremely high level of concentration if even fairly obvious faults are all to be identified, to say nothing of more minor finishing issues and stains. To avoid the problem of “looking but not seeing” inspection staff should not spend more than 45 minutes at the most before being relieved.

The removal of stains is fundamental to the service offered by cleaners; failure to remove them is a common complaint and (in the absence of an advice note) frustrates, irritates and annoys customers and clearly demonstrates that, at the very least, the inspection procedure needs to be improved. No cleaner can afford to risk disappointing customers by failing to deliver on the basics and a thorough, detailed final inspection procedure prior to polyrobing is the only way to ensure that mistakes are kept to an absolute minimum. The inspection procedure should address the following questions:

- Is the item clean and stain free?

- Has it been finished to the required standard?

- Presentation – have zips been checked and if necessary lubricated, back pocket buttons fastened and so on.

- Have any additional services such as a new zip or replacement buttons been done.?

Every garment should be systematically inspected all over and the total of faults identified. It is a mistake to return an item as soon as a fault is found as there may be additional faults that need correcting in sequence; so, if there are stains and a finishing error, the stains need priority. Many finishers will have experienced the wasted time and the frustration of having finished a garment that they then find themselves finishing two or three times, because it had been re-cleaned when additional stains were found after it had been returned to final inspection.

Presentation is an important aspect of the final inspection procedure helping to ensure that differing garment types are all delivered back to the customer in the best possible condition.

Presentation specification

The following specification was developed by The Fabric Care Research Association to ensure that the appearance and functional features of garments could be consistently maintained at a high standard in storage by means of the final inspection procedure.

There will of course always be cases where, due to the style or design of an individual garment, one or more of the presentation points for that garment would not be appropriate.

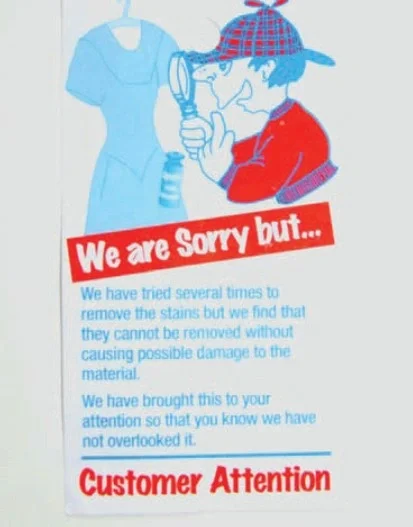

Final inspection is your last opportunity to avoid a disappointed customer. It is not good enough for a garment to be spotlessly clean and well finished, because if the zip is stuck it is totally useless. It is not difficult to imagine the anger when a customer has collected their garment on the way to the airport only to find at their destination that a tailor repair such as an alteration or replacement zip has not been done. Make no mistake: it is a big deal if a garment has to be returned by the customer, so when you have done your best and an explanation is needed, make sure your advice notes deliver well-written, professional information and don’t use caricatures which make a joke out of failure, they send the wrong message to a disappointed customer.