Acetate

Acetate may also be blended with other fibres. It can be found in a wide range of clothing including wedding gowns, party wear and garment linings. Acetate fabrics are at risk of glazing if ironed above 110C. so ensure electric steam iron thermostats are correctly adjusted for a cool setting before finishing.

The main risk with acetate and acetate blends is that acetate is soluble in acetone a spotting chemical used by some cleaners. Acetone is particularly effective for the removal of nail polish and it is used in nail polish removal products. If acetate is exposed to a single drop of acetone, fabric damage is instantaneous and irreversible and as acetone products are used in the home environment, ladies clothing is highly vulnerable. So look out for any sign of damage during reception to avoid any misunderstandings further down the line. Damage may look like a glue stain, a circular stiff area or an area where the fabric appears to have melted and in some cases loss of colour.

Acrylic

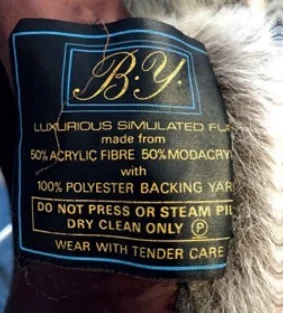

Frequently used in the manufacture of knitwear, acrylic fibres are very heat sensitive. Acrylic fibre is also used in the production of furnishing pile fabrics where it often comes under the brand name Draylon. Cleaners also need to be particularly aware of modacrylic fibre occasionally found in faux furs and trims. Modacrylics, Dralon and acrylic pile fabrics are particularly heat sensitive and should ideally be dried at below 50 deg C and should not be finished. To avoid the risk of pile / fibre distortion, it is critical that all pile fabrics and furs are removed from the machine immediately the cage stops rotating at the end of drying. If left in the machine after rotation has stopped, creases may be introduced in the pile which it will be impossible to remove.

As knitted fabrics are not dimensionally stable, irrespective of the fibre type, it is always a good idea to measure them prior to cleaning. When exposed to the heat of drying acrylic knitwear can easily be stretched out of shape in drycleaning and it can then be extremely difficult or impossible to restore the correct dimensions. To avoid the risk of distortion confine knitwear closely in a net bag for cleaning and when steam finishing knitwear do not touch or move the lay before it has been fully cooled with vacuum.

Polyester

Perhaps the most common of all the fibre types, versatile, strong and hard wearing polyester really is a great textile, it responds well to dry or water based processes and is frequently blended with cotton or with animal hair fibres for use in personal wear. While cleaners rarely experience problems with polyester if things do go wrong they can be terminal. There are two risk areas which all cleaners should be aware of.

- If washed above 50deg C and not cooled down correctly permanent creases may be set into polyester fabric. This is known as thermal shock and to avoid the risk of damage, if washed at higher temperatures, the rinse temperature must be strictly controlled and slowly reduced at no more than 5C per minute until it reaches 50C.

- Poor detergency and/or classification in washing and particularly poor classification in drycleaning can result in permanent greying of white polyester fabrics or fibre blends. It is also the case that polyester is oleophilic and clings tenaciously to oily or greasy soiling. In particular it may not be possible to completely remove black oily stains even with paint remover.

Bear in mind that both thermal shock and greying can be introduced in the home so if you are experiencing problems with cleaning or finishing polyester the customer could be responsible.