I will be honest with you, for the 50 plus years I have hated and loved doing trouser creases in equal measure. I think that it is long overdue that I rant about them, and I am sure experienced pressers who are reading this will recognise these situations.

When things go right, it’s great, but when you get one of those pairs of trousers that never sits nice and flat on the hanger, no matter how many times you re-laid the trousers legs on the press to ensure the creases were correct. Those are the times when one wishes that creases in trousers were not popularised by King Edward VII and that trousers were best pressed flat..,

Resin creases

I remember when sales of resin creases in trousers was being heavily pushed by competing dry cleaning groups of the time and was commonly called permanent creasing, but would be given their own “pet name” by the companies.

And while training of the staff to apply the resin crease, was for the most part adequate but often rushed, they were all under pressure to meet and beat sales targets. in fact to the extent that trousers that were made of fabric that was much too thin to take the creases would sometimes have the resin bleeding through to the outside of the fabric.

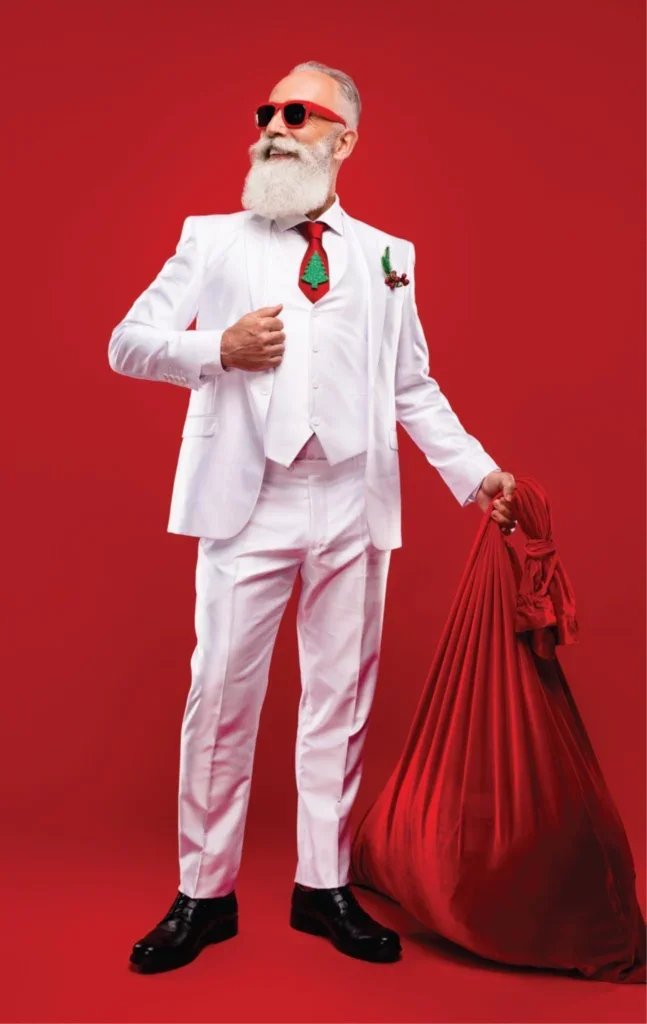

One of my least favourite jobs was to remove the resin creases that were put into the wrong type of trousers (which sounds like a Wallace and Gromit Film). It was not easy and a specially designed product had to carefully be applied to the crease for the resin to soften and then be removed by rubbing the glue away without causing damage to the fabric. Within my resin removal kit. I had my own set of guitar-type plectrums (shown in the photo) the edge of these were used to gently rub the resin until it had softened and was removed in another dryclean.

Now imagine how tedious a job that was on one pair of trousers with creases front and back over several hundred branches and just 10% of the branches made an error once per week and sent them to me to be removed. That is 240 creases which equals a lot of time spent by me in removing them.

Sewn-in creases

Another popular thing to get done was in the 1970s and 1980s to have ones creases sewn in. This would normally involve the presser setting the creased into exactly correct positions and the seamstress running a sewing machine as near to the edge of the crease as possible.

This was a very popular thing for police officers and security guards to ask about and many a pair of serge wool trousers looked much smarter for it – for a while at least, until the areas of fabric tension around the knee on them would result in the fabric getting stretched these areas and the sewn in crease now sitting in a wavy drunken line down the legs.

Lightweight Italian superfine wool lined trousers

These are usually out of hibernation in the spring. They will be recognised as they are often put away at the end of the previous summer without being cleaned. This is not to say that the owner is a slob, but usually has forgotten the champagne that spilt down them and dried invisibly only to be forgotten about over months of winter.

A bit of advice here, based upon experience. Even if the owner has declared that they are stain-free and only being brought in for a freshen up, don’t be fooled. A few seconds being steamed on the press before cleaning will soon show up all these sugary drink stains and you can treat them prior to cleaning rather than find them after cleaning just as you are pressing them.

It is also often worthwhile to show the owner the stains as many genuinely have forgotten about spillage.

The lightweight, lined superfine wool trousers often take several times as long as normal trousers in pressing, so it is always worth spending that bit of extra time at the beginning.