Since the early 2000s, food industry technicians have been getting ever more concerned about allergens in food products and the duty of care they owe to their ultimate customer – the everyday consumer. As their research revealed the danger that even minute amounts of allergens on foodstuffs can have on sensitive adults (and even more so on affected children), precautions in food processing have been escalated. These now extend, quite rightly, to the workwear which they issue to their operatives. Instances of illness and death from the unwitting consumption of foodstuffs containing trace amounts of common allergens have made newspaper headlines.

In the UK, the workwear garment rental sector has responded with its own research, to produce a sequence of procedures which have been designed to reduce, to a very low level, any risk of potentially harmful allergens contaminating any food industry workwear garment. They have identified a set of marker allergens, which can be quantitatively detected on fabrics and surfaces, and used these to monitor wash process adequacy and the laundry decontamination performance actually achieved.

The tests used and the frequency with which they are applied are proportionate to the risks addressed, and have produced an integrated and cost-effective scheme, establishing in the process the powerful benefits of a nationwide garment rental programme.

It is noteworthy that this success has been achieved by cooperation between the food processors and garment rental operators, without any legislative interference from government!

Decontamination process development

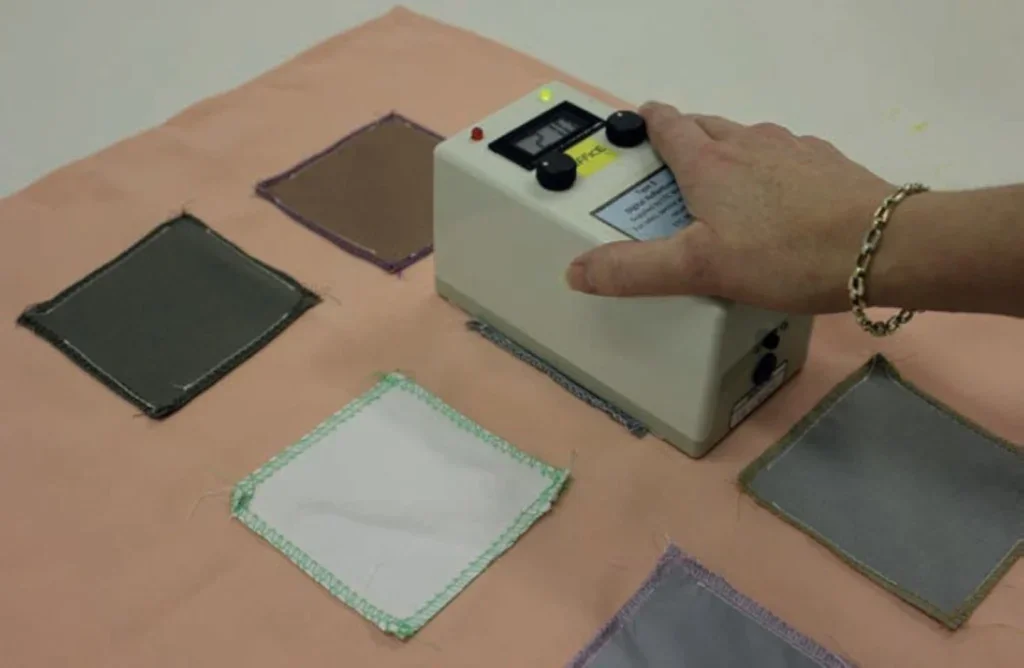

Effective removal of proteins is critical to allergen decontamination, because most allergens are protein-based, with a wide variety in the proteins concerned. Research has found that a one-wash test piece based on dairy protein, animal blood and carbon black can provide reliable indication of animal protein removal from this soiling. The Swiss EMPA organisation offers a calibrated test swatch based on these ingredients and the power of the wash process with respect to protein removal can be assessed numerically using a standard laundry reflectometer. The effectiveness of this is now backed up by several years research data on multiple sites throughout the UK, which demonstrate its reliability.

Bleaching of vegetable dyes, usually by oxidation, complements protein removal, allowing visual checks by the food industry customer. A stain-free appearance is an essential part of assured decontamination. Some oxidising agents also offer a destructive effect on any stray residual molecules of protein.

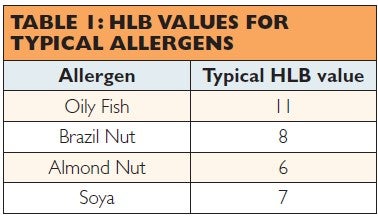

Removal of vegetable oils is vital, with some unrefined nut oils, which contain the nut protein being particularly important. These, along with any fatty proteins, need suitable emulsifiers, to allow effective reduction using low temperature washing. Animal and human body oils usually need a different emulsifier to that used for dairy and for nut oils, so a wide-range emulsifier is called for. This could be a blend of two or more different emulsifiers to span a range of HLB (hydrophilic-lipophilic balance) values, from perhaps 15 right down to 6 for some nut oils and leading laundry chemical suppliers have achieved this in the last few years. Removal of mineral oils is essential as the HLB of mineral oil is closely matched to some fish as well as some nut oils. Most allergen decontamination processes also provide sufficient power to remove these if the HLB value is appropriate.

Control of re-deposition of soiling removed by detergency is critical to allergen

decontamination. There is a natural tendency for micelles of emulsified oil and particulate soiling to be attracted back onto the clean fabric before the end of the wash process. This is because the soiling in suspension in the wash liquor tends to acquire an opposite electrical charge to that on the surface of the clean fabric. This creates a strong attraction which results in re-deposited soiling locking onto the cloth surface, where it is very firmly held, causing overall greying. This can be very difficult to reverse in any rewash. Greying assessment can be used to monitor the degree of re-deposition occurring. Re-deposition is countered by including powerful suspending agents in the wash chemistry, which wrap around the suspended soiling (in all of its forms), neutralising the electrical charge. This, together with the physical barrier to re-deposition created by the wraparound effect, reduces to a low safe level any risk of re-deposition of allergens on the clean textiles.

How the garment rental operator is providing justified assurance of adequate allergen removal

Allergens cannot be seen with the naked eye and can even be difficult to recognise under strong magnification. Leading laboratories have developed qualitative and quantitative tests for particular allergens, but these are time-consuming and require specialist equipment and skills. They are not suitable for daily, weekly or even monthly quality control in the rental laundry, but they are suitable and cost-effective for evaluating different decontamination processes and for annual monitoring and certification of laundry performance.

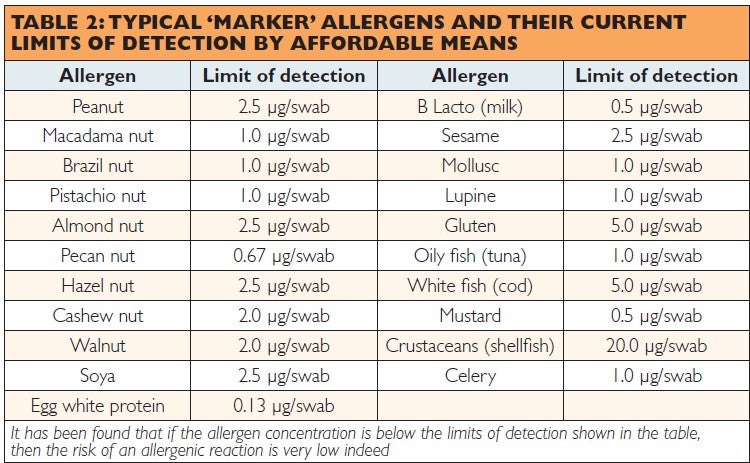

LTC research has shown that the decontamination performance of a rental laundry can be assessed by measuring the allergen contamination on key surfaces and on a representative sample of decontaminated garments. There is no need to perform these tests for every one of the hundreds of different allergens in foodstuffs. It has been found that if the level of a limited number of key ‘marker’ allergens is below the current detectable limit, then the risk to the consumer has been reduced to an adequately low level and cleansed garments from the plant can be safely used. These detectable limits for some common allergens are shown in Table 2.

In between annual testing and certification, quarterly test have been developed and proven, to ensure that the power of the wash process continues to match or exceed that required. These quarterly monitoring tests are based on calibrated EMPA single-wash test swatches to indicate (numerically) the removal of animal and dairy protein, mineral oil, vegetable oil and vegetable dyes. They also include the use of a 25-wash test swatch for greying, to indicate the level of redeposition of soiling back onto the clean textiles.

Experience to date

The systems developed by LTC have now been used in the UK for many years and have been shown to be highly effective, with costs which are deemed proportionate to the risks. Laundry staff have been trained to oversee the quarterly test washes in-house (which greatly increases the speed and reduces the cost). The onewash test pieces give very few problems; the 25-wash swatches for re-deposition occasionally get lost, but putting these under the control of a single person with an effective monitoring form has largely sorted this out.

Contamination of the re-deposition test-piece with dye tints from coloured workwear (or logos or braiding) has also been a problem (because this gives an apparently poor numerical result). This has been largely solved by only monitoring re-deposition using the test piece in the middle of a run of white garments) which minimises dye contamination. The system is deemed to be both simple and workable.

Where do we go from here?

It is a credit to the laundry sector and its suppliers that the systems described have been initiated, developed and installed without the intervention of government legislation, which has probably enabled much quicker success, without tedious and unnecessary bureaucracy. The food industry has been critical to this success, by providing regular laundry inspection visits and working with the sector and its suppliers to solve each problem as it emerged. LTC Worldwide conducted the research work and test development and developed each of the protocols which underpin the staff training and integrated assurance. The R&D work itself was supported in part by the UK government, to which due acknowledgement is made. It is important for the food industry and garment rental sectors to retain the lead they have taken, and they appear to have every intention of doing this.

Consumers worldwide appear to be getting more sensitive to allergens, even in minute trace amounts. This could mean that we can expect the resilience of the human body to become less tolerant of trace irritants in the future. The alarming nature of allergic reactions includes the potential for anaphylactic shock and even death. If this becomes more common and if more species start to give problems, then the garment rental sector needs to be at the forefront of sorting this out. We may need to increase the number of marker allergens in our tests and be able state how we will increase the decontamination power of or processes. Fortunately, we have laundry chemistry suppliers with the technology to raise the power in several different ways to cope with new allergens. We also have the ability to vary the textiles used in garment construction, to further improve soil release and re-deposition potential.

Conclusion

For many years, contract launderers and textile rental operators have struggled to market products and services for which price has been the dominant arbiter. Now at last we have the opportunity to sell the essential technical quality of our service in this sector and talk about the decontamination assurances we can offer!