Staff shortages, ever-increasing cost pressures and growing demands in the area of sustainability pose major challenges for laundries worldwide. New technologies, such as automation, can offer solutions, says Kannegiesser, but there is no one universal solution. In order to set the right course for the future, a detailed analysis and expert advice are crucial. The result: a concept customised to requirements. The basis for this is formed by state-of-the-art technologies in the areas of sorting, automation, SmartLaundry and sustainability.

Sorting solutions: precision and efficiency at the highest level

Sorting is a central process in every laundry. Kannegiesser sets standards with innovative technologies. The sorting solutions from Kannegiesser are as diverse as the laundries themselves and are tailored to the various phases of the laundry process. On the soiled and clean side, systems or machines can sort items as required: by size, colour, barcode or RFID chips. This means that the specific requirements of each laundry can be met.

The introduction of the automatic soiled laundry sorting system from Kannegiesser represents a major step forward in the automation of laundries. The system uses RFID chips in the laundry items to automatically identify the laundry and sort it into laundry trolleys or bags. It also uses X-ray technology to recognise foreign objects in the garments to prevent machine damage and ensure staff safety. This also works for heavy industrial workwear.

Another revolution in sorting technology is the SFM-E large-part folding machine for flat linen. It automatically sorts and stacks up to six different article types such as bed sheets and tablecloths in 1 and 2-lane operation. Differentiation can be made according to size, appearance or using RFID.

In the area of garments, Kannegiesser is presenting the TLL system, which uses RFID technology to automatically match garments with hangers within a small tunnel. Unlike other solutions, the TLL system significantly speeds up the identification process and ensures that garments are identified faster and more reliably than ever before. Employees no longer have to match garments to hangers themselves during the loading process. This not only simplifies the workflow, but also increases efficiency and accuracy when processing garments.

Automation that sets new standards

In response to the growing demand for automation to overcome staff shortages and increase productivity, Kannegiesser is presenting new solutions in the areas of robotisation and software.

Highlights include the automatic dry laundry line with the Robofeed RFT feeding robot and the Speedline folding machine. This system automatically separates, folds, sorts and stacks mixed batches of towels from hotels and hospitals. This is made possible by the use of advanced camera technology in combination with ServoTronic. This enables peak outputs of well over 800 and average outputs of around 650 items per hour.

SmartLaundry: digitalisation for the laundry of tomorrow

The SmartLaundry eXperience from Kannegiesser presents a range of innovative solutions for automating, optimising and simplifying laundry processes.

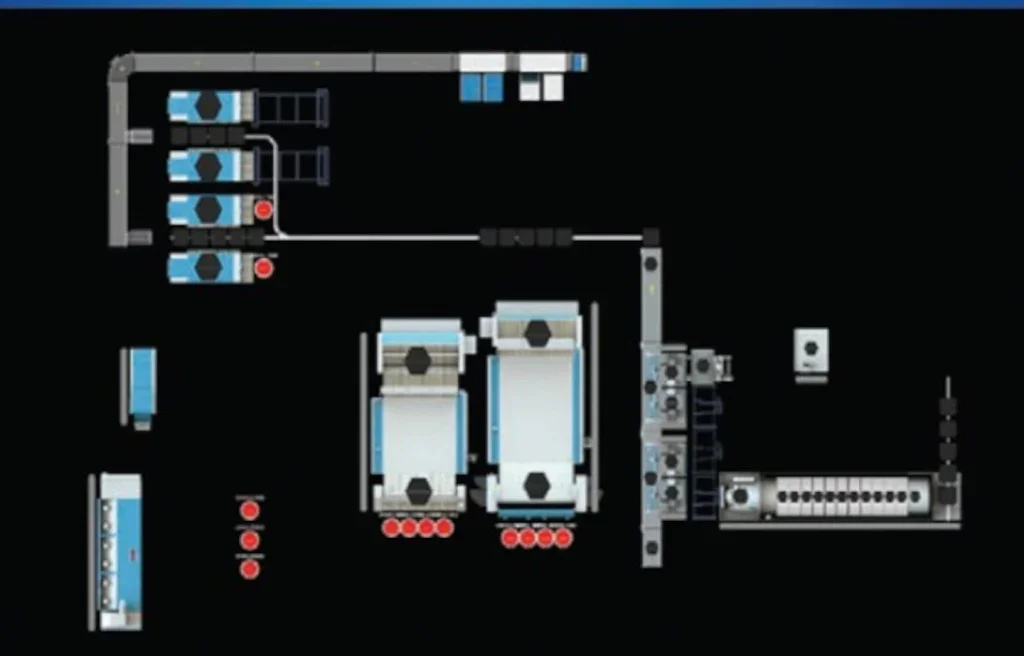

SmartVue is a graphical user interface that enables laundries to visualise their entire operation on a virtual map. Operators can call up information on individual machines, check performance and even track the location of laundry batches for individual customers in real time.

In addition, BatchPrinting and Pack&Label offer practical solutions to optimise processes even in smaller laundries. BatchPrinting enables automatic and therefore reliable program selection, even when using laundry trolleys. By printing machine-readable tickets after unloading the dryer, laundries can create a seamless flow of information from the wash to the finish area. Operators can scan the barcode information on the ticket at the mangle line or dry laundry folding machine and immediately call up the correct processing program. In the expedition, Pack&Label is the reliable solution for complete and fast order picking. The laundry trolleys are labelled for dispatch using automatically generated packing lists, which display the article quantities for each customer.

The Supertrack bagging system is controlled by eVue Control. This means that the laundry always has an overview of all laundry items in the system. The simple and intuitive system offers full transparency with a wide range of information, a control system customised to the process and clear diagnostic functions. This enables the laundry’s logistics to be optimised.

Sustainability: efficient and future-proof

Sustainability is not just a trend, but a necessity for modern laundries. The latest innovations from Kannegiesser help to reduce energy and water consumption in order to cut costs and minimise the ecological footprint.

The XStream tunnel finisher is a prime example of how innovation can further reduce energy consumption. With its newly designed counterflow concept, the three-module XStream achieves the same efficiency as a standard four-module tunnel finisher, saving time, energy and space.

The PowerDry is the most powerful and efficient transfer dryer on the market. The innovative Eco2Power process control combines minimum energy consumption with maximum performance in the drying process. It enables a low energy consumption of 1.1 kWh/l of evaporated water while simultaneously reducing overall process times.

The HighPower ironer with its unique stainless steel heating belt technology enables maximum performance with significantly reduced energy consumption. A HighPower 2-roller ironer has the same performance as a conventional 3-roller ironer.