Many of the day -to-day items handled by cleaners have trims and adornments, some of which, when exposed to dry or wetcleaning processes, may be damaged or have the potential to damage other items in a load of work. Items such as buttons, beads, sequins, diamantes, stuck on glitter and lace to say nothing of a host of other addons such as polyurethane or faux trims all continue to cause serious problems for the cleaner. This month we look at how to identify some high-risk items, test and assess the risk and where appropriate, protect them. For example, it is wise to establish the parameters when checking the care label at the counter.

Care labels

As regards the accessories just mentioned, it is important for the cleaner to understand what is and what is not covered by drycleaning and washing/wetcleaning symbols, because, in the event of a failure in cleaning, this will be of considerable help in discussions with the customer (especially if responsibility is thought to lie with the retailer and manufacturer). The straightforward answer is that if accessories are integral with the garment and could not be reasonably be removed, they should be covered by the care label; if they can be removed, they could well not be covered. Unfortunately, the quality and performance of accessories in cleaning often leaves a lot to be desired and is frequently not reflected in the price of the item, meaning that cleaners need to pay particular attention to accessories and care label information when accepting high value and designer garments.

Checking and protecting items can be vital, for example:

Buttons

The loss or damage to just one feature button on a designer or high value garment, as cleaners may be aware, can lead to much time and effort sourcing a replacement and perhaps an expensive claim if one cannot be found. The solution here is to discuss the problem with the customer at reception and agree an additional charge for removal and replacement – no method of protecting buttons can absolutely guarantee their integrity particularly in drycleaning.

There are several methods available for protecting buttons. Traditionally heavy grade aluminium foil has been used to wrap around them and, with the exception of very large buttons, this offers reasonable protection against physical damage.

Plastic dome protectors (button bobs) are easy to apply and close and lock around the shank. They afford good protection for a range of medium sized buttons but in our experience are not always appropriate for buttons on very delicate items such as a silk blouse.

Beads

Very small beads are often chain stitched so careful inspection prior to cleaning is essential, if the loss of a large number of beads is to be avoided. In the majority of cases, garments are cleaned with beads attached and these areas can be protected by covering the beads with cotton sateen, lightly tacked into place. Alternatively, the garment could be cleaned in a fabric bag (as opposed to a net bag) – not an ideal solution for white and light-coloured garments.

Diamanté

Diamanté ‘stones’ deserve special and detailed attention as they have the potential to cause untold damage to garments during cleaning. The metal clasps holding the stones in place often have sharp points some of which are not in direct contact with the stone and present a serious snag or scratch hazard for any delicate fabric, particularly lace, chiffon and satin.

Check every stone and where necessary press any projecting points back into place, this can be time consuming and tedious but better safe than sorry. Where possible and appropriate cover the area with cotton before cleaning.

Stuck on glitter

No cleaner should underestimate the damage and cost to the business that glittered fabrics can generate, if a quantity of glitter is liberated into a load during cleaning. All fabrics with stuck on glitter will lose some during a cleaning process and if the particles become embedded in the fabric structure of other garments, it can be extremely difficult or impossible to remove them, leaving the cleaner open to a major claim. Some of the released glitter may also become entrained in any lint or debris adhearing to the machine inner surfaces, only to be released during a subsequent, load possibly contaminating other garments!

The answer is to clean any glittered items in a fabric bag or decline to accept them.

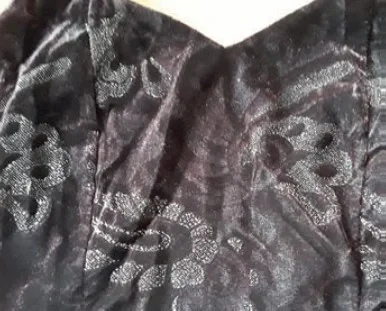

Sequins

Metal and plastic are commonly used in the manufacture of sequins and both types can deteriorate with wear and repeated cleaning, colours becoming patchy or faded. Sequins may be chain stitched, so once again this demands very carful inspection prior to cleaning. Always check the colour fastness of sequins using a white cloth moistened with water and detergent or the solvent you are using. Metal sequins can be susceptible to variations in appearance over a period of time and plastic in particular may show a very slight change in colour when subjected to steam finishing, so steam two or three before you start. If sequins are attached to a removable base, it is generally better to remove them before cleaning or cover them with cotton sateen lightly tacked to the base.

In the past, some sequins were made using gelatine. Gelatine sequins are badly damaged if washed and instantly shrivel when subjected to steam, so with very old garments it is essential to remove a sequin and steam it. Ideally this should be done before the garment is accepted for cleaning.

Lace and crochet fabrics

These open structure fabrics are particularly at risk from diamanté and clasps and other adornments on the garments they might be cleaned with.

Make sure during reception that the fabric is intact and undamaged. In conjunction with a reduced cleaning cycle, placing the garment in a fine net bag for cleaning will provide a good level of protection.

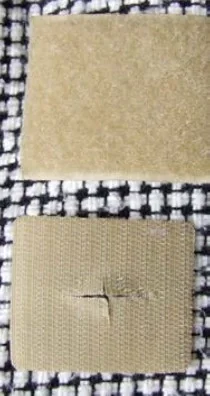

Trims and faux fabric

Today many garments, a good example being duffle coats, have patches, panels or trims made from a variety of materials including PVC, Polyurethane and faux leather all of which can degrade during wear through exposure to sunlight or abrasion, exposing them to the possibility of further serious deterioration during subsequent drycleaning or wetcleaning. PVC and faux leather materials with a PVC content, may go brittle, hard and shrink slightly when drycleaned. Cracking and hardening of PVC. is almost inevitable if drycleaned in perc, due to the removal of the plasticisers used in manufacture. The degree to which an item may be affected depends on condition prior to cleaning and the solvent used, with hydrocarbon and Green Earth probably contributing little to any pre-existing trim failure.

Polyurethane panels, trims and patches are very susceptible to deterioration, due to flexing and abrasion in wear, and should therefore be very carefully checked during reception for any sign of the surface coating starting to lift or flake off, as it can only get worse if cleaned. These materials are often of limited durability and our advice is, do not deviate from the care label information and if in any doubt it is better to decline to accept the garment rather than risk disappointing the customer.

Faux leather and suede are generally very good imitations of the real thing and the cleaner may have difficulty in determining if the trim or patch is genuine leather or suede. Some faux leather/suede trims may have a P.V.C. component and therefore will be particularly at risk if cleaned in perc. In the case of designer/high value items, if you are not confident of the response of the trim to drycleaning, (bear in mind that genuine skin may fade or lose colour), agree owner’s risk with the customer or decline to accept the garment.

Glitter ruins three suits

Fault: this cocktail dress had an overall design created with glitter. It was cleaned in perc in a normal load of dark suits in a net bag. All the glitter was stripped off and deposited on the suits and could not be removed from three of them.

Responsibility: the dress was wrongly labelled – the glitter adhesive was soluble in perc., so the maker and retailer are responsible. However, the cleaner will probably have to take responsibility for the contamination of the other customers garments, because having accepted the dress it should have been cleaned with delicates on a reduced cycle and cleaned in a fabric bag, to prevent the escape of glitter.

Rectification: the contaminated suits could not be rectified and resulted in a major payout for the cleaner.

Sticky beads ruin coat

Fault: after testing the beads, this heavily black-beaded white coat was placed in a fabric bag and cleaned in perc. Some of the beads disolved while others remained unaffected.

Technical Cause: although the beads appeared to be all the same it is highly likely some were not from the same batch and were manufactured from polystyrene which is not resistant to perchloroethylene.

Responsibility: the retailer/manufacturer should be take responsibility here, because the cleaner cannot be reasonably be expected to test every bead. The aftercare information ‘Dry Clean Only’ was inadequate as it did not define which solvent could safely be used.