The forthcoming EXPODetergo exhibition in Milan, 21-24 October, is going to be the first chance for the European market, including the UK, to vet new developments in dry/ wetcleaning. Some of those developments will have been aired for the first time at The Clean Show in Atlanta, USA, in the summer. Here is a selection of big brands showing their wares in Milan, starting off with chemicals providers.

Drycleaning is catered for by various solvents, such as perchloroethylene, hydrocarbon solvent or silicone solvent in the form of the trademarked Sensene. Büfa was involved in the developing of Sensene over several years.

Sensene, an alternative solvent based on modified alcohols, is distinguished by its gentle yet high solvency power, stable formulation and its ability to simplify workflow since less pre-spotting and finishing efforts are required. It is also inherently biodegradable and equals an environmentally responsible way of drycleaning, says the company.

This enabled the introduction of perfectly balanced textile care, says Büfa, allowing textiles to retain their colour brilliance and just smell clean (not of solvent). Valuable textiles, especially outerwear, sportswear, weatherproof clothing, duvets, protective clothing (PPE), must be cleaned and treated professionally, it says.

Kreussler is a German family business founded in 1912, managed by the fourth generation. The invention of the original wetcleaning and SYSTEMK4, two sustainable solutions for colour and fibre-preserving cleaning of non-washable textiles, are just two of many textile care innovations.

Realstar engineers have collaborated closely with the Kreussler in developing chemical products for the drycleaning industry, to offer new machines that will maximise results utilising the new Class III A solvent, SOLVON K4. Realstar will be introducing the VISION series.Designed for use with alternative solvents such as hydrocarbon ands silicone, Vision machines produce sparkling clean clothes without the use of water or steam, says Realstar.

Union’s CLOUD L’s main features are cleaning by water mist and low temperature dry steam, with main parts made from stainless steel, Dialog microprocessor control and a large loading door. Find a wide range of machinery engineered for a variety of drycleaning machines. With capacities from 8 to 140 kg, Unisec machines guarantee durability, says the company.

More owners are choosing to move to more sustainable products such as Cole & Wilson’s HiGlo, as an alternative to perc when it comes to drycleaning, says the company. “ The main factor being that it’s a more environmentally-friendly solvent but also that is allows improved safe cleaning of delicate items.

Delicate and expensive, designer items can be confidently cleaned knowing that the chemicals are safe and produce a great end result. Cole & Wilson provides training on the best use of the chemicals, how to deal with all different types of fabric and stains. HIGLO leaves textiles with a smooth, soft touch, due to limited pilling and roughening and an added fullness along with a neutral smell. It works well on delicate garments with beads, sequins and trimmings, making it a very versatile option for the modern dry cleaner. Handling process times are also reduced, less time required for finishing means more garments can be turned around in a day.

Equipment

Barbanti offers a vast range of machines for industrial finishing to meet all the needs of various sectors; from wet cleaning to dry cleaning, from clothes manufacturing to Horeca, for hotels and communities with its high quality, certified, patented professional equipment.

Fimas, a member of Macpi Group, is capable of responding to the different needs of the market because of resultant synergies. enabling the ability to supply the smallest laundry up to the biggest ones.

Fimas offers a wide range of high quality and flexibility machinery, such as steaming cabinets (with or without doors), dummies, vacuum, blowing and steaming ironing tables (with interchangeable shapes), spotting tables and pressing machines, able to satisfy the different working realities.

Meanwhile Firbimatic has a wide range of drycleaning machines for the different markets of the world and for use with both standard and alternative solvents. Firbimatic’s most recent introduction is the new Vortex series designed for use with perchloroethylene solvent. Its new Concept S using the latest engineering and design technology offers fast cycle times by greatly reducing the drying phase.

Meanwhile, on stand 3264, along with Seitz, Girbau will present the Poseidon solution which incorporates highly-programmable wetcleaning machines and moisture-sensing and reversing dryers. Visitors will have the chance to learn first-hand how to program and use these products, and to discover their advantages.

Grandimpianti has been operating in the laundry industry since 1972 offering machines and equipment for the professional wetcleaning, drying, ironing and treatment of linen. Its machines are characterised by maximum reliability, high quality, low consumption and reduced maintenance costs. They include washers, tumble dryers and roller ironers.

Drycleaning machines, washers, tumbledryers, and hygienising cabinets and auxiliary equipment is available for all sectors from Italclean whose machines are based on easy maintenance, reliable and extremely user-friendly machines with a long service life.

Macpi manufactures pressing machines for garment producers and industrial laundries, designing customised machinery based on the needs each business and offering complementary services, maintenance and after-sales service. Macpi says the best companies in the apparel industry and the world’s leading fashion houses will be on its stand.

Maestrelli is one of the most important producers in the drycleaning sector, with more than 40,000 machines sold and major clients anywhere in the world, from Europe to Middle East and from the south-east to the Americas. The company was also the first Italian producer ever, being founded in 1935. Maestrelli is widely known for its high-quality standards, for cutting-edge technology and last but not least for the solidity of its machines, says the company.

Metalprogetti is at EXPODetergo to “present what’s new, meet historical partners, make new agreements, measure ourselves against the competition and identify the strong market products. Gathering feedback is important to target new areas of research and development to invest in”. Metalprogetti products were born as storage and warehouse management RFID solutions, evolving over time into increasingly automated systems, such as sorters, employee uniform dispensers and personal garment pick-up systems. Pony is a leading Italian manufacturer of pressing and finishing equipment with a wide range of products that include ironing tables, presses for laundry and drycleaning, shirt finishers, formers of any kind, spotting tables and cabinets, trousers toppers, steam generators and sanitising machines.

“We know that quality service means comprehensive assistance and constant innovation,” says Rampi. It has always been committed to providing solutions designed to safeguard the health of workers in laundries because quality means above all ensuring the end customer a service that respects the health of all those involved along the supply chain.

Realstar has, in consultation with customers, agents and market requirements developed a new range of perchloroethylene drycleaning machines. The R series machine has been developed to be technically advanced, a compact machine, with easy operation and has been fitted as standard with many features for maximum performance and reduced operating costs. Realstar hydrocarbon machines are available as KT (2 tanks) KM (3 tanks) and HSK (suspended drum for high-speed spin).

Innovation, quality, and new product lines covered by exclusive patents: these are pleasant surprises that visitors to EXPODetergo will be able to admire when visiting the Renzacci stand. In the drycleaning field the focus will be on a concept of cleaning strictly related to wellness and health, thanks to the new bio drycleaning machines from the exclusive Sentinel edition, which takes advantage in a simple and innovative way of the natural power of ultraviolet rays for a deep and effective action against virus and bacteria.

Last but not least is the new generation of sanitising and hygienising cabinets with triple combined action i-Genius 2.0, to provide a high-quality service to all customers in the hospitality industry.

Rotondi produceshi-tech pressing equipment for mens and ladies jackets, trousers, jeans, shirts and knitwear. Two advanced production plants of almost 10,000 square meters (100,000 square feet) give an integrated manufacturing cycle from design to completion using the latest automatic cutters and robots.

Sankosha recognises that after two years of Covid a lot of people need to train to achieve skills in textile knowledge, spotting, finishing, and so on. Sankosha is dealing with that shortfall more automation and practical hi tech solutions to help its customers meet customer demands. Sankosha is focusing on advanced solutions and isintroducing specialised machines for high quality finishing for bigger volumes.

Seitz is a leading manufacturing company present in more than 70 countries with a team of professionals happy to assist exisifting and potential customers.

Sidi Mondial manufactures pressing and finishing equipment including ironing tables, presses for laundry and drycleaning, shirt finishers, formers of any kind, spotting tables and cabinets, trouser toppers and steam generators.

Meanwhile, Trevil designs and produces professional equipment for garment finishing and electric steam generators for industrial use.

Visitors to EXPODetergo can find a wide range of machinery engineered for a variety of drycleaning machines with capacities from 8 to 140 k from Unisec.

“Our machines guarantee durability,” says the company.

BÖWE LETS THE LIGHT IN OVER ‘BLACK OVER’

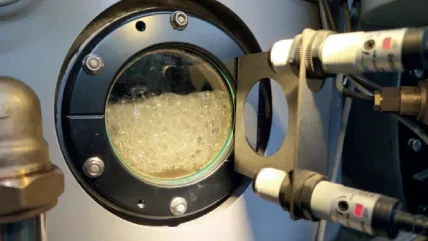

Ever since drycleaning machines have been in existence, the problem of distillation boil over (also known as black-over) has been a problem. Due to the addition of low temperature boilers such as water, high humidity, dosing additives and substances removed from the garments during the drycleaning process, the boiling behaviour of the solvents and the low boiler mixture can change. This results in froth and a ‘black-over’ of the distillation. This problem is particularly problematic with alternative solvents.

Böwe decided to tackle this situation and developed a new photoelectric sensor. During the distillation process, the surface of the liquid in the distillation is monitored. If there is increased bubble formation, the sensor detects this and automatically breaks the vacuum for a short time. This leads to an increase in the boiling point and a collapse of the foam head. Black-over and dirt transfer are thus prevented. This eliminates the need for annoying and expensive cleaning of the water separators and clean tanks, which leads to odour formation if poorly maintained. In addition, energy-intensive distillation of contaminated tank contents is no longer necessary which saves a lot of energy, time and cooling water. Problem solved!