At the upcoming Texcare International 2024 exhibition , expect to see an increase in robotics and AI in the field of feeding and folding. It really is the ideal place for this technology and great strides have already been made from the likes of Jensen/Inwatec, Kannegiesser , Laundry Robotics and others.

Since late 2023, Mads Andresen, selfconfessed laundry nerd and founder and CEO of Inwatec ApS is now the visionary force behind Jensen Group’s innovation journey. As chief innovation officer and member of the executive management team, Andresen will oversee advancements in all Jensen-Group’s cutting-edge technologies.

Seamless integration

His mission is to seamlessly integrate robotics and machine learning into the DNA of the Jensen-Group. The ultimate goal is to establish Jensen as industry leader in sustainable solutions and the effective capture and utilisation of data, benefiting customers and internal operations.

Andresen, a prominent figure in the field, is the founder and CEO of Inwatec ApS, the celebrated #laundrynerds from Odense, Denmark.

The Jensen-Group recognised the rising demand for automated solutions employing robotics and AI. “Throughout our fifth year of collaboration with Inwatec Aps, numerous new laundries were established across all continents, where robotics were seamlessly integrated alongside tunnel washers and finishing lines. These automated solutions contribute significantly to the overall sustainability of laundries by extending the lifespan of textiles and machines while ensuring the highest standards of health and safety,” said Jensen-Group CEO, Jesper Munch Jensen, when announcing record profits fcor the ocmany back in March.

In 2023, the Jensen-Group achieved an unprecedented revenue milestone of €400.1 million, compared to €341.6 million in 2022, representing exponential growth of 17.1%.

In more news for Jensen-Group, less than eight months after the announcement of the signing of an OEM Original Equipment Manufacturer agreement with the company Prima Folder of Ravenna/Italy, the Jensen- Group is pleased to announce its entry into the capital of Prima Folder with a 33% stake, formalised on 31 May.

With this transaction, both companies intend to strengthen their presence in the finishing and folding sector of heavy-duty laundries, by offering their customers a new range of small parts feeders and folders, complementing the world-renowned Jensen ironers and adding to the existing Jensen range of feeders and folders.

Founded in 2005, Prima Folder has become over the years a benchmark in the field of small piece feeders and folders, thanks in particular to its TAU Feeder and the GAMMA with variable format flip flap folders.

The Jensen-Group aims at completing its existing range of feeding and folding of small pieces with Prima Folder equipment, in order to offer its customers, the ‘Made in Italy” folding recognised in the world of restaurant linen as a high-quality folding process.

“The Jensen-Group already started distributing the Prima Folder machines a few months ago, and we are looking forward to working even more closely with our new Italian colleagues from Prima Folder,” confirmed Clément Silvaggio, chairman of the Board of directors of Prima Folder.

Over the past decade, the industrial laundry industry has undergone a remarkable transformation due to the emergence of artificial intelligence (AI), says Erwin Massen of Laundry Robotics. “This technological advancement has resulted in more efficient processes, improved service quality, and cost savings. The most notable developments in recent years include process automation (determining the appropriate cleaning methods), energy consumption optimisation (streamlining drying times), and quality control (inspection for stains and holes).

“Automation in the industry is expected to rapidly increase further. More processes will be optimised using AI, enabling laundries to operate more efficiently and strengthen their competitive position. Robotics, coupled with AI, will increasingly play a larger role in industrial laundries. In the coming years, we will witness significant deployment of autonomous robots (such as feeding robots and transport robots) in industrial laundries. In Europe, it is projected that within three years, robots using AI will handle 20% of the towel feeding and the laundry sorting tasks, rising to 80% within seven years. AI-driven quality control will significantly increase due to this robotic integration.

Subsequently, there will be a shift towards more sophisticated robot solutions capable of executing complex tasks.

Robotics

Back in 2022, at EXPOdetergo in Milan, Laundry Robotics’ Robin and Roy robots burst on ti the scene automatically feeding your towel folder whatever brand and whatever type. Check out Robin’s performance in a ‘human v machine’ test here. The Laundry Robotics team is available alongside the Biko Engineering team at the show. We look forward rto see whatt they have to offer this year.

Laundry Robotics exhibited its initial version of the Robin automated towel system almost a decade ago and has moved from strength to strength in the years since.

The machine has changed dramatically since those early days with the company working closely with its clients to improve upon that original model. And not wanting to rest on their laurels it then released a baby brother for Robin, called Roy, at Expo Detergo in 2022.

Philip Ghosh of Biko UK, distributor for Laundry Robotics in the UK and Ireland, says: “With Texcare fast approaching in November, I am looking forward to seeing what fresh and exciting ideas will be on the stand.”

Laundry lines

“I believe that laundries will not be able to survive without robots in the future. All laundries are experiencing a shortage of staff,” says managing director Bernhard Ostermann of Ostermann

Textilpflege laundry, based in Esterwegen in north-west Germany, which has been in business for almost 60 years. The laundry’s recipe for success includes a constant drive to modernise. “Over the decades, we have always pushed ahead with further developments.

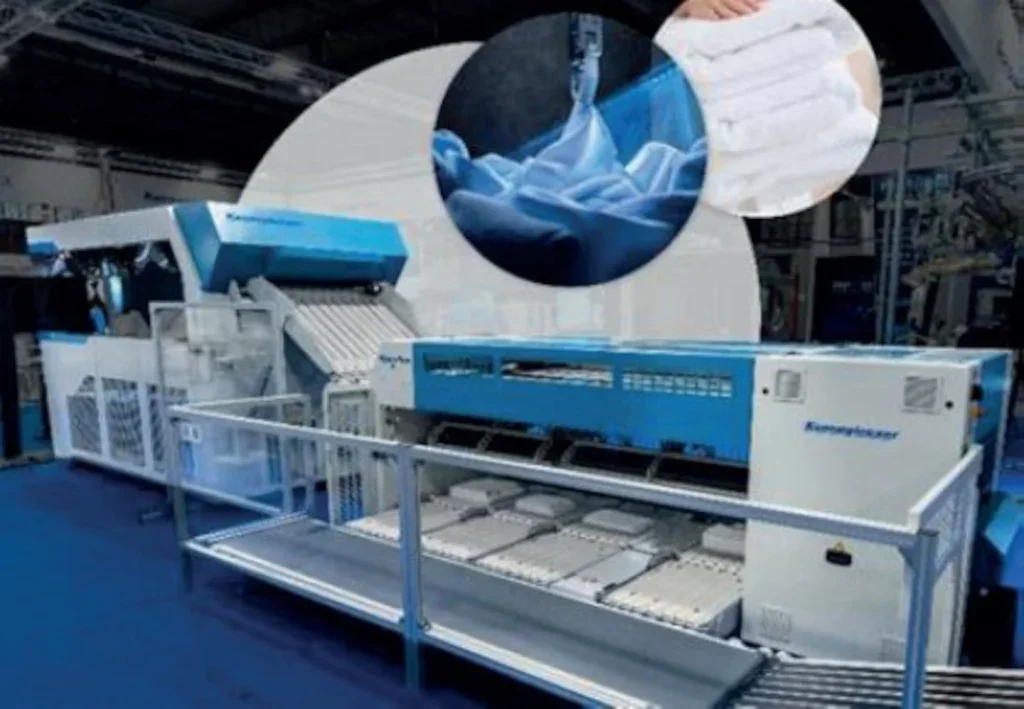

“The next step is robotics: since 2023, the automatic dry work line by Kannegiesser has been the heart of the laundry. The special feature here: Presorted laundry batches are loaded manually from the laundry trolleys into the dry work line – without a fully automatic monorail bag storage system.

“The robot has the advantage for us that we are much faster in production. This means that the items come out of the machine more continuously,” says Ostermann. “At 700 items per hour, the output meets Kannegiesser’s specifications.” He adds that the system achieves this output, for example, when processing mixed batches for hotel customers with hand towels, shower towels, bath towels and bath mats.

After drying, the batch is pre-sorted manually: Finally, the finished stacks receive packing slips via the Kannegiesser Pack & Label system. “With the Pack & Label connected, the robot can develop its full potential,” says Ostermann.

Technological solutions

In the rapidly evolving textile care industry, CLMTexfinity is dedicated to revolutionising laundry processes through advanced technological solutions. From small-scale operations to high-volume industrial environments, CLMTexfinity aims to deliver unmatched quality and sustainability, ensuring every fabric receives the care it deserves. This commitment to innovation is what makes CLMTexfinity a trusted partner in the textile care industry, consistently pushing the boundaries to meet the dynamic needs of its clients, says the company.

CLMTexfinity believes its feeding and folding solutions, a critical aspect of textile care, underscores the company’s prowess in delivering comprehensive and state-of-the-art systems. “The innovation embedded in these solutions not only enhances operational efficiency but also sets new benchmarks for quality in fabric finishing. This dedication to excellence is what positions CLMTexfinity as a leader in the industry, ready to showcase its capabilities in the specialized arena of feeding and folding,” says a spokesperson.

CLMTexfinity offers a range of feeders tailored to diverse laundry operations, each designed for high-quality and highspeed feeding. The S.feed s is engineered for high production laundries, offering 3 or 4 stations for excellent feeding precision. The S.feed m manual feeder combines reliability with a robust design, while the S.feed r provides a customized solution for remote feeding, optimizing high-speed ironing lines. These feeders exemplify CLMTexfinity’s commitment to maximizing operational efficiency and reliability in textile care.

The S.fold series from CLMTexfinity showcases specialised solutions for folding various textile items with precision and speed. The S.fold l is designed for large pieces, offering customizable folding options and stacker configurations to meet diverse operational needs. For smaller items like napkins and pillowcases, the S.fold s ensures neatly stacked and folded results.

Flexibility

From Foltex comes FlexFeed LP1 which is a versatile feeder for laundries processing many small customers. The machine can be operated by 1 or 2 operators.

Meanwhile, The FlexFeed LP2 is the most simple spreader feeder in the market. With 2 operators, this feeder offers great productivity and with the option of feeding directly in the spreader clamps as well, also special linen can be processed. The patented transfer system guarantees the highest feeding quality.

The FlexFeed LP3 and LP4 are the Foltex high production feeders, available in 1 and 2 lane execution. High production combined with high feeding quality is secured by the patented transfer system.