When a customer comes into a high street unit carrying a clearly expensive leather or suede item, alarm bells should ring. Leather goods are renowned for producing unpredictable results, even in the hands of very experienced professional cleaners. High street units are rarely equipped with the spraying, recolouring, re-oiling and pressing equipment and the skills necessary for handling leather goods and many cleaners sub-contract these to a specialist. However, the receiving cleaner still needs to exercise professional care when accepting the garment and offer suitable advice and realistic expectations.

This month we look at the knowledge and skills required to minimise disappointment and preserve the confidence of the regular customer, so as not to place at risk their monthly contribution to your turnover with easily handleable textile goods.

Why are leathers so difficult to clean with confidence?

There are very few quality standards worldwide relating to the drycleanability of a leather garment and care labelling for this. However, there are four superb British Standards which together would give the consumer much better protection if only they were to be used consistently and effectively!

- BS 6453:19841 gives a simple specification for garment leather, to enable a tanner to produce material with the shrinkage potential, colourfastness and performance in wear and cleaning necessary to ensure customer satisfaction.

- BS 7269:1991 Part 12 gives performance criteria for the maximum permissible changes in drycleaning of a new garment range, regarding shrinkage, colour change, loss of finish and so on. This standard even incorporates a simple care labelling scheme for garments which meet this performance standard.

- BS 7269:1991 Part 23 gives a straightforward method of test to indicate to a distributor or retailer that a new leather garment range does actually meet the performance standard.

- There is also a method for determining the colourfastness of garment leather to drycleaning in an important British and international standard: BS EN ISO 105-D02:20164. This is used principally for assessing the colourfastness of textiles, but it is designed to be equally applicable to leathers. It assesses, in a reproducible standard manner, the amount of mark-off obtained when garment leather is rubbed with a piece of white cotton cloth soaked in the cleaning solvent to be used. Many cleaners already use a crude copy of this method when assessing potential loss of colour in cleaning!

Development of these standards involved leather experts from the former British Leather Research Association, leather cleaning experts from the former Fabric Care Research Association, leather tanners and garment makers. These people knew what they were doing and produced workable, pragmatic guidance.

All four of these British standards are marked: ‘Status: current’; they are not obsolete, and there is no good reason why they should not be used. Yet even highquality stores specialising in expensive designer goods and buyers for major chain stores persist in continuing to import ranges which are frequently inadequately specified, not properly tested and labelled with marking which is often misleading or incorrect!

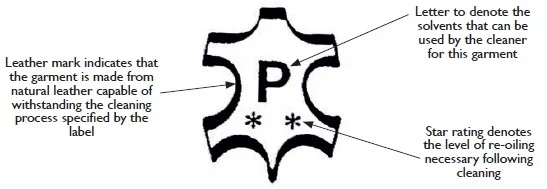

The standards are capable of providing considerable help to the frustrated consumer faced with a ruined garment, if that result was the consequence of leather of inadequate quality or poor garment labelling in the first place. Where a British Standard exists, if the care label is suspect, the customer is entitled to ask the retailer for a copy of the test certificate to verify that the range was actually tested and that the leather met the necessary performance standard. It is even quicker to establish whether it provides the information called for in the British Standard or whether the label itself is sub-standard, simply by comparing the label with the illustration given here. These are areas where the receiving cleaner can provide really helpful advice to a disappointed customer.

Care labelling of leather and suede

suede The illustration below describes one of the symbols in the novel care labelling code given in Part 1 of BS 7269:19911. The symbol is framed by the standard international leather mark, denoting that this is a genuine natural material, not a plastic imitation. The solvents recommended are denoted by the letter in the centre of the leather mark. Capital P indicates that the garment can be cleaned in either perc or solvent 113. This solvent has now been phased out, but experience with hydrocarbon solvent has shown that it gives results comparable with solvent 113. However, due to the diversity of suede/leather cleaning systems (one bath drycleaning and wetcleaning are now in common use throughout the industry), the degree of re-oiling actually required will depend very much on the specific process employed by the cleaner, using their hands-on experience to determine the actual amount of leather oil required (which will vary with the speed and duration of the extract phase of the cleaning cycle).

Conclusion

It is difficult to comprehend how the present situation has arisen, given that current performance and care labelling standards exist, to prevent widespread poor quality and incorrect care labelling across the entire range of leather garments on sale in the UK. When discussing leather garment problems with customers, cleaners should not hesitate to explain this and point customers in the right direction with the invaluable information given here.

Panel to panel variation

Fault: this leather garment carried a care label consisting of a leather mark containing the letter F with three asterisks beneath it. When the cleaner processed it in perchloroethylene solvent, with a normal charge of leather oil, there was significant variable colour loss and significant shrinkage.

Technical cause: the leather mark with the letter F indicates that the garment cannot be cleaned in perchloroethylene, only in hydrocarbon or similar mild solvents. The cleaner might also have succeeded with a very mild solvent such as cyclosiloxane (which has a lower solvency power than hydrocarbon and the same drying temperature) but perchloroethylene has stripped out the colour and probably all the leather oils, hence the shrinkage. The three asterisks within the leather mark indicates to the cleaner that this garment also needed higher than normal levels of leather oil in the final solvent bath to maintain the fullness and enhance the colour.

Responsibility: if the cleaner had been able to recognise the label and its meanings then this fault could have been avoided.

Rectification: if this garment is re-cleaned in hydrocarbon with a maximum charge of leather oil (see the suppliers’ recommendations) and finished with careful use of steam and vacuum it may just be possible to recover the shrinkage. Colour variation between panels is fairly common in drycleaning and in many cases the colour in the faded panels can be developed, without recourse to spray dyes, by carefully spraying the affected panels with an emulsion of sulphited cod oil in water.

Ugly stains appear in cleaning

Fault: previously unstained seams and hems on two garments came out with unsightly blotchy dark marks after cleaning in perchloroethylene. The garments both had the textile cleaning symbol on the care label.

Technical cause: the glue used here to make the hems on these garments is slightly sensitive to the drycleaning solvent specified and has softened and moved during the solvent wash. Some has come to the surface and made it tacky, attracting and retaining dark soiling from the cleaning fluid. The care label is incorrect for this garment.

Responsibility: this lies with the garment makers. There are garment adhesives available which do not give this problem and a care labelling system which would have advised the correct solvent to use.

Rectification: If the garment were to be recleaned in perchloroethylene solvent, there is a very slight chance that all of the adhesive might be removed. The hems could then be refixed. Otherwise, the garment should be treated as ruined and returned to the retailer.