North America’s largest event for laundering, drycleaning, textile care services, supplies, and equipment is back after a hiatus due to Covid and the textile services industry is on tenterhooks to catch up on new developments – and with one another in person. The Clean Show, say the organisers, creates a platform that brings together all industry professionals to network, educate, and share the latest technologies in the industry.

It is the premier event for the commercial laundering, drycleaning, and textile service industry in the United States/North America, and the event stands out as a beacon, signalling that we are putting the dark days of the pandemic behind us and welcome a new dawn.

Elsewhere in this edition of LCNi, ETSA’s secretary general Elena Lai points to the importance of international exhibitions for networking, communication and synergies. “All of you can come and exchange views and information and make business. Go to exhibitions!” she urges.

Look foward to live demonstrations, networking opportunities, and educational sessions where industry experts will share the latest technological advancements hitting the industry, trend predictions, strategies to grow and expand into new markets, and insights on how to stay ahead of the competition.

The Clean Show is organised under the Texcare umbrella in collaboration with five industry-leading US associations: Association for Linen Management (ALM), Coin Laundry Association (CLA), Dry- cleaning & Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA), and Textile Rental Services Association of America (TRSA).

National trade associations from around gthe qwoeld will be visiting with their officials and members taking part in debates, discussions and ogthr events, notably those fielded by the North American textile rental association, TRSA, which has organised a raft of learning opportunities around the show.

Specialised sessions throughout the week provide opportunities for business operators to educate themselves and their teams with topics like Hygienically Clean and Clean Green Certification programs, global industry trends, how to protect your customers, employees and business assets with contracts and more.

ABS

On the exhibition floor ABS, stand 4228, will be there with news that Vitec Software Group AB has acquired all shares in ABS Laundry Business Solutions (ABS). ABS reported sales of SEK 203 million for the 2021 financial year.

ABS was founded is the global market leader in software for the laundry industry. ABS focuses primarily on multi-plant industrial launderers active in various industries, predominantly healthcare, hospitality, and industrial verticals such as construction and manufacturing.

ABS serves over 650 laundry facilities across 5 continents, with more than 15,000 active users. With offices in the Netherlands, United States, Romania, France, Belgium, Germany, Denmark and Japan.

"ABS has 35 years of experience, and the company is the leading independent provider of software for the global laundry and textile rental industry. The advanced functionality sets the company ahead of its competition and installations of ABSSolute, in some cases with over 1.000 concurrent users, are business critical for customers worldwide," says Olle Backman, CEO, Vitec Software Group.

"I am convinced that together we will continue to develop ABS for the benefit of our customers and staff today and in the future," says Anne de Boer, CEO, ABS Laundry Business Solution.

Christeyns

Another merger is that of UNX Industries and Christeyns USA which have announced they are entering into a definitive merger agreement to create UNX-Christeyns. The new US-based company will be able to deliver an unparalleled portfolio of chemicals, detergents, engineered equipment and cleaning solutions to the commercial and industrial textile care market, said the company.

At the same time, Christeyns is launching EPIC, an innovative detergent system. EPIC stands for Enzymatic Process Innovation by Christeyns and is based on enzyme technology, enabling laundries to reduce their waste costs by 25%.

Danube

"Because wellness is also our concern,"says Catherine Gouneau, Danube (stand 2514) for many years has been developing a range of laundry equipment specifically designed to guarantee all customers laundry hygiene and disinfection."

Danube shows its range of barrier washer-extractors for the health sector and nursing homes. With these machines, also available in dual-energy heating, not only are the risks of cross-contamination reduced, but they allow significant energy savings. Completed with one of the company's Ø 500- or 650-mm flatwork ironers, equipped with built-in lengthwise folder and rear exit, laundry performance is improved. An ozone cupboard, which can disinfect any type of textile or accessory that cannot be water washed is a perfect complement to washing machines in a healthcare facility or a laundromat.

“Danube is also committed to respecting the environment and optimising resources: so all our washers and dryers are equipped as standard with many features to save energy, water, or detergents thanks to the ET2 microprocessor as well as many options guaranteeing the efficiency of our models by adapting perfectly to the needs of each one. five concepts define our machines: high performance, energy efficiency, connectivity, robustness, and versatility,” says Gouneau.

Domus

Meanwhile, Domus, in its centenary year has a lot to celebrate as Gemma Colomer explains: “At Domus, we know how important efficiency is, and we are very aware of our commitment to the environment. That is why we have developed new technologically advanced equipment and solutions with low energy consumption and high production efficiency.

“At Clean Show, (stand 2514) we are exhibiting different solutions and equipment to suit all types of laundries: from hospitality, hotels, healthcare sector, to the coin laundry sector. This year, a new series of 45, 60, 80, 100 and 120 kg washing machines stand out, which completes and renews our already extensive range of washing machinery. These washing machines come equipped with Domus’ Ecovolution technology which easily enables IoT connectivity and traceability plus superior efficiencies in water and chemicals.

Dryers in various ranges up to 80kg have features that guarantee high efficiency such as air recirculation and an intelligent humidity sensor. Ergonomics have also been taken into consideration with the introduction of a wide hatch sliding door, standard reverse drum action and air filter in-drawer for easy maintenance.

Also look out for smaller capacity washers and dryers, down to 8kg and the ECOTANK accessory to recover wash water.

Girbau

Girbau will unveil its latest innovations in industrial, commercial, vended and textile care laundry solutions on stands 2118, 2112 and 2106. Girbau is the industry’s most diverse provider of commercial, industrial, vended and textile care laundry solutions, according to president Mike Floyd. Stands 2118 and 2112 will be dedicated to commercial and industrial laundry, while 2106 will focus on vended laundry solutions.

“During Clean, we promise exciting booth interaction, educational product demonstrations, and valuable opportunities to speak with continental end-users, distributors and team members,” said Floyd. During the show, visitors will also enjoy aggressive financing and product promotions.

The company will present its complete range of washers and dryers, including the new line-up of Genius soft-mount washers for commercial and vended applications, which feature easy installation, high-speed extraction of up to 450 G-force, and superior productivity and performance. It will also feature multi-housing laundry solutions, and Girbau Industrial’s high-volume ironing, multi-sort folding and stacking systems, including the new DRC cornerless feeder, which offers up to three feeding stations and accommodating items up to 3.5 meters ironing widths;

Girbau will also showcase its new high-speed DRE feeder, which precisely feeds healthcare and hospitality linens, as well as napkins and pillowcases. The new Compact PRO ironing system, which combines five functions in a single unit: feeding, drying, ironing, folding and stacking, all at speeds of up to 25 metres a minute, and the new FTQ Folder – which automatically folds drywork items of different dimensions one after the other, including towels, bathmats, washcloths and blankets.

Meanwhile, on stand 3264, along with Seitz, Girbau will present the Poseidon solution which incorporates highly-programmable wetcleaning machines and moisture-sensing and reversing dryers. Visitors will have the chance to learn First-hand how to program and use these products, and to discover their advantages.

Jensen

Productivity and robotics meet in creating the future in laundry automation at Jensen, stand 506 Smart technologies and new materials handling solutions are opening up great new perspectives for heavy-duty laundries says Jensen’s Gerda Jank. “We invite you to explore these new perspectives and exchange ideas with our laundry experts from all over the world.

“Our investments in laundry robotics, artificial intelligence and Big Data confirm our vision to automate all processes in the laundry,” she explains.

“We are excited to show you the brand-new THOR robot engineered by our partner Inwatec. THOR automatically separates all soiled articles, meaning T-shirts, uniforms, towels and flat linen. Depending on the article size, THOR can handle up to 1500 pieces per hour. Automatic separation improves the employee health and safety, as it reduces the risk of injuries and infections. On top of that, the equipment is safe. The robot picks up the laundry pieces from conveyor belts and transport them to the X-ray scanner, which detects unwanted objects hidden in the pockets. At the same time, an RFID chip reader registers the garment and determines further sorting in the system. All these tasks can now be performed by a few operators who only have to empty the pockets of the discarded garments. The new THOR allows no distinction between linen or garments.

“Quite a few laundries all over the world have become pioneers in their field, utilising robots from Inwatec to automase the soil sort," says lank, adding that visitors can experience a live demonstration of THOR combined with a Futurail loop that bulk loads the soiled system to increase laundry capacity and free up floor space.

Big volumes require big machines. The new XR dryer will process big cakes with a diameter of 51 inches. The wider opening also allows a faster unloading, with savings of 10-20 seconds per batch: Laundries can process more loads within one shift thanks to the new AirWave feature. AirWave also speeds up the subsequent finishing process with its unique blow-out, reducing tangling of linen. XFlow ensures a 10-15% higher evaporation capacity over the whole width of the burner box and optimises the heat distribution for an even and fast drying process. The XR' s precise and well-dosed heat control, InfraCare, reduces the energy consumption and the drying time, while extending the lifetime of the linen. The control detects varying weights and residual moistures, and avoids unnecessary energy supply and long drying times.

In the finishing section, the new Express Pro feeder will double the PPOH in laundries processing laundry from the healthcare, hospitality, and food & beverage sectors. It’s a cornerless feeding system that excels at high speeds. A mechanical transfer beam with a leading edge holding bar replaces the vacuum section. In the receiving position, the holding bar is open while the leading edge is held between the transfer beam and a fixation tube. During the transfer, the holding bar is closed, ensuring a fast and efficient transfer into the machine. As a consequence of the high capacity, the number of ironer lines may be reduced allowing to free up space for other equipment.

A simplified version is offered with the new KliQ feeder that features a new generation of feeding clamps – a masterpiece of operator convenience. This simple and space-saving solution is available with a Concorde-shaped nose for direct feeding, eliminating the need for an inlet table on the ironer. Both feeders stand for high and uniform finishing quality and high productivity.

On the stand, the K1iQ and Express Pro feeders are combined with the new Kando folder, also a much-wanted innovation for laundries serving the healthcare, hospitality and F&B sectors. Building on the DNA of the Jensen folder range, the Kando incorporates fully adjustable air blast pressure in the lateral folding section and reversing conveyors in the cross fold section, ensuring optimum folding quality for all types of flatwork.

As the total length matches the well-proven Classic folders, the Kando folder is a perfect solution for replacement of existing Classic folders.

Premium folding quality at high speed can also be discovered in the new Fox 1200 garment folder – a well-proven machine concept for the full range of garments and uniforms. Using a new servo-drive motor at the hanger release and a new conveyor at the first cross-fold, the Fox 1200 processes up to 1200 garments per hour in mixed production. The new design of the cross-fold section along with upgraded software ensures outstanding folding quality. Moreover, this new cross-fold section adapts perfectly to material of various thicknesses. A servo-driven hanger release safely and quickly transfers the garments from the Metricon conveyor system into the Fox folder.

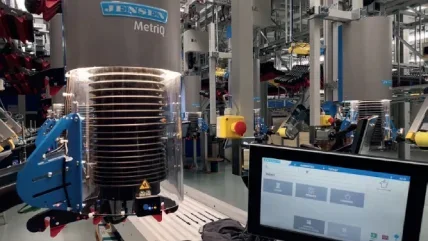

Meanwhile, the Metricon garment handling and sorting system presents the new MetriQ loading station, pictufred above. Featuring the unique 'buttons-to-the-front' option for e.g. patient gowns and scrubs, garments of all types can be loaded without any time loss by moving to the opposite side.

A further highlight is the new GeniusFlow solution that ties the laundry together and gives proof of how smart technologies boost the productivity: The sorting robot communicates the recorded data from the soiled side to the garment sorting area in real time.

By using this information collected from tag reading, the Metricon Software combines various customers and routes into lots and sublots and then allocates the exact space needed in the primary storage. This reduces the need for extra rails and prevents a high recycling rate, which decreases sorter efficiency. The interface allows a simpler management of garment batches and reduces the number of late garments to be processed manually.